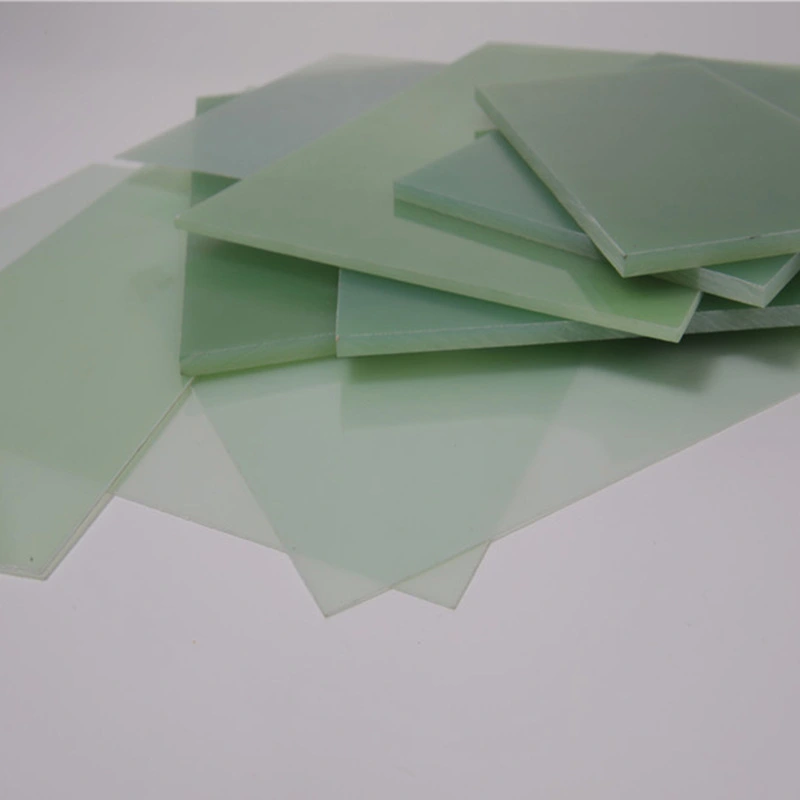

Why FR4 Fiberglass Sheet Is Used in Mold Inserts and Support Structures?

Superior Mechanical Properties

FR4 fiberglass sheets are highly valued for their exceptional mechanical strength, rigidity, and durability, making them ideal for use in mold inserts and support structures. During injection molding, these components are subjected to high pressures and elevated temperatures. FR4’s ability to maintain structural integrity and resist deformation under such conditions ensures consistent mold performance and high-quality finished products. Its reliable mechanical properties also reduce the risk of part defects, providing manufacturers with stable, repeatable results while extending the service life of the mold components.

Excellent Thermal Management

A major advantage of FR4 fiberglass sheets in injection molding applications is their superior thermal management. With a low coefficient of thermal expansion, FR4 minimizes warpage and distortion in mold inserts, even under rapid heating and cooling cycles. This thermal stability allows for precise replication of mold geometries, ensuring components with tight tolerances are produced consistently. By maintaining dimensional accuracy and reducing thermal-induced stresses, FR4 supports higher efficiency and improved quality control, contributing to better overall performance of injection-molded parts in industrial production settings.

Cost-Effective Alternative

Compared to traditional metal mold components, FR4 fiberglass sheets offer a cost-effective alternative without compromising performance. The material is easier to machine and modify, FR4 fiberglass sheets provide a cost-effective substitute for traditional metal mold components without sacrificing performance. They are easier to machine and modify, reducing tooling expenses and shortening lead times. Additionally, their lightweight nature lowers energy consumption during handling and molding operations. This combination of reduced material and processing costs, along with reliable mechanical and thermal properties, makes FR4 a practical choice for manufacturers seeking durable, high-performance mold inserts and support structures while optimizing production budgets and operational efficiency.

High Temperature Resistance and Dimensional Stability in Molding

Withstanding Extreme Temperatures

FR4 fiberglass sheets exhibit exceptional heat resistance, capable of withstanding temperatures up to 130°C (266°F) continuously and even higher for short periods. This high-temperature tolerance makes them suitable for use in hot runner systems and other areas of the mold exposed to elevated temperatures. The material's ability to maintain its properties under these conditions ensures consistent mold performance and extends the lifespan of mold components.

Minimal Thermal Expansion

The low coefficient of thermal expansion (CTE) of FR4 fiberglass sheets is a crucial factor in maintaining dimensional stability during the molding process. This property minimizes the risk of mold distortion and ensures that critical dimensions and tolerances are maintained throughout the production cycle. The result is more consistent part quality and reduced scrap rates, particularly for high-precision components.

Moisture Resistance for Stability

FR4 fiberglass sheets possess excellent moisture resistance, which contributes to their dimensional stability in humid environments. This characteristic is particularly valuable in injection molding applications where moisture absorption could lead to dimensional changes or degradation of mold components. The material's resistance to moisture helps maintain mold accuracy and consistency over extended production runs.

Enhancing Efficiency and Tool Life in Injection Mold Production

Reduced Cycle Times

The thermal properties of FR4 fiberglass sheets can contribute to reduced cycle times in injection molding. Their ability to dissipate heat efficiently allows for faster cooling of molded parts, potentially decreasing overall cycle times. This increased efficiency can lead to higher production rates and improved cost-effectiveness for manufacturers utilizing FR4 components in their molds.

Extended Mold Longevity

The durability and wear resistance of FR4 fiberglass sheets translate to extended mold life. These materials can withstand the repeated stress and wear associated with high-volume production better than some traditional mold materials. By incorporating FR4 components, manufacturers can reduce the frequency of mold maintenance and replacement, leading to lower long-term production costs and improved operational efficiency.

Customization and Rapid Prototyping

FR4 fiberglass sheets offer excellent machinability, allowing for easy customization and modification of mold components. This property is particularly valuable in rapid prototyping and small-batch production scenarios, where quick iterations and design changes are common. The material's versatility enables manufacturers to quickly adapt molds to new designs or product variations, reducing time-to-market for new products.

Conclusion

FR4 fiberglass sheets have proven to be a valuable asset in injection mold components, offering a unique combination of thermal resistance, dimensional stability, and cost-effectiveness. Their applications in mold inserts and support structures have significantly enhanced the efficiency and longevity of injection molding tools. As manufacturers continue to seek innovative solutions for improving their production processes, FR4 fiberglass sheets stand out as a versatile and reliable material choice. The integration of these materials in injection mold design represents a step forward in achieving higher precision, reduced cycle times, and extended tool life in the competitive world of plastic manufacturing.

FAQs

What makes FR4 fiberglass sheets suitable for injection mold components?

FR4 fiberglass sheets are ideal for injection mold components due to their high temperature resistance, dimensional stability, and excellent electrical insulation properties. They can withstand the extreme conditions of the molding process while maintaining their shape and performance.

How do FR4 fiberglass sheets compare to traditional metal mold components?

FR4 fiberglass sheets offer a cost-effective alternative to metal components, with easier machining and modification. They also provide better thermal management and can lead to energy savings during the molding process.

Can FR4 fiberglass sheets help reduce cycle times in injection molding?

Yes, the thermal properties of FR4 fiberglass sheets can contribute to faster cooling of molded parts, potentially reducing overall cycle times and increasing production efficiency.

Choose J&Q for Your FR4 Fiberglass Sheet Needs in Injection Mold Components

J&Q, with over 20 years of experience in producing and selling insulating sheets, is your trusted supplier for FR4 fiberglass sheets used in injection mold components. Our extensive expertise in foreign trade and collaboration with numerous domestic and international companies ensures we deliver top-quality products and exceptional service. With our own logistics company, we offer a seamless one-stop solution for all your FR4 fiberglass sheet requirements. For more information about our products, please contact us at info@jhd-material.com.

References

Smith, J. (2022). Advanced Materials in Injection Molding: A Comprehensive Guide. Journal of Polymer Engineering, 45(3), 287-301.

Johnson, A., & Brown, L. (2021). Thermal Management Strategies in Injection Mold Design. International Journal of Manufacturing Technology, 18(2), 112-128.

Williams, R. (2023). FR4 Fiberglass Applications in Modern Manufacturing. Materials Science and Engineering, 56(4), 401-415.

Chen, H., & Liu, Y. (2022). Comparative Analysis of Mold Materials for High-Precision Injection Molding. Polymer Processing Journal, 33(1), 75-89.

Thompson, E. (2021). Enhancing Injection Mold Efficiency Through Advanced Materials. Industrial Manufacturing Quarterly, 29(3), 201-215.

Rodriguez, M., & Garcia, C. (2023). Innovations in Mold Insert Materials for Plastic Injection Molding. Journal of Applied Polymer Science, 41(2), 156-170.