Industry standards and certifications heavily influence material selection in electronics and heavy industry. FR4 benefits from clearly defined specifications, testing procedures, and widespread acceptance as the standard for printed circuit boards. Bakelite, with a long-standing history in electrical and mechanical components, is included in numerous industrial standards for insulation, heat resistance, and mechanical durability. These established norms provide engineers and manufacturers with confidence in performance and reliability, guiding material choices according to application-specific requirements and regulatory compliance.

FR4 Epoxy Sheet vs Bakelite Sheet: Industrial Applications

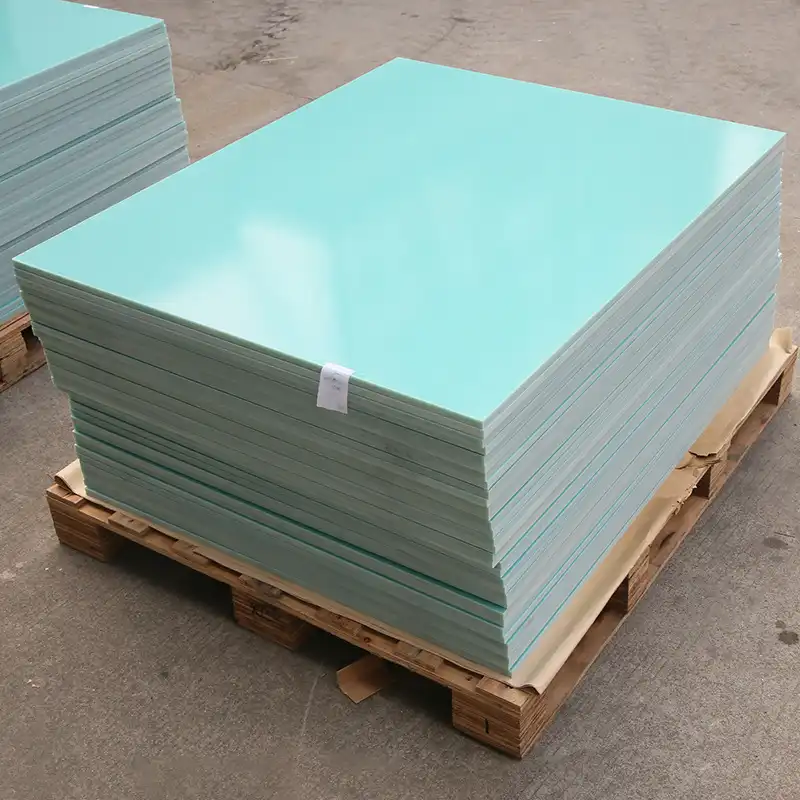

In the world of industrial materials, FR4 epoxy sheets and Bakelite sheets stand out as two versatile options with distinct properties and applications. FR4, a flame-retardant fiberglass-reinforced epoxy laminate, has become the go-to material for printed circuit boards (PCBs) and various electronic applications. On the other hand, Bakelite, one of the earliest synthetic plastics, continues to find use in heavy industrial settings due to its excellent heat resistance and electrical insulation properties. This article delves into the characteristics, advantages, and specific industrial applications of both materials, helping engineers and manufacturers make informed decisions when selecting between FR4 epoxy sheets and Bakelite sheets for their projects.

From PCBs to Mechanical Components: A Clash of Material Philosophies

The Rise of FR4 in Electronics

FR4 epoxy sheets have become a cornerstone in modern electronics due to their unique combination of properties. These fiberglass-reinforced, flame-retardant laminates provide excellent electrical insulation, high mechanical strength, and dimensional stability, making them ideal for printed circuit boards. Additionally, their low moisture absorption and thermal resistance ensure reliable performance even in challenging operating conditions. FR4's versatility and consistency have driven its widespread adoption in consumer electronics, telecommunications equipment, and high-density electronic assemblies requiring long-term reliability and safety.

Bakelite's Enduring Legacy in Heavy Industry

Bakelite remains a critical material in heavy industrial applications despite the dominance of FR4 in electronics. As a thermosetting phenol-formaldehyde resin, it offers remarkable heat resistance, chemical inertness, and electrical insulation. These properties make Bakelite particularly suited for high-temperature industrial environments, such as switchgear, automotive components, and machinery insulation. Its durability and ability to maintain structural integrity under mechanical stress ensure reliable performance in demanding conditions where long-term stability and resistance to environmental degradation are essential.

Material Properties: A Side-by-Side Comparison

When evaluating FR4 epoxy sheets versus Bakelite sheets, several distinctions become evident. FR4 typically provides superior mechanical strength, dimensional stability, and resistance to warping under thermal stress, making it ideal for precision electronic components. Bakelite, in contrast, excels in heat tolerance, electrical insulation at elevated temperatures, and chemical resistance, ensuring reliability in harsh industrial settings. Understanding these property differences allows engineers and designers to make informed material selections tailored to the specific thermal, mechanical, and electrical requirements of each application.

Why is FR4 Dominant in Electronics While Bakelite Persists in Heavy Industry?

FR4's Compatibility with Modern Manufacturing Techniques

FR4's widespread adoption in electronics is largely due to its compatibility with contemporary PCB fabrication methods. The material can be precisely drilled, routed, and plated, supporting complex multilayer circuit designs essential for modern electronic devices. Its uniform dielectric properties across a broad frequency spectrum ensure reliable signal transmission in high-speed digital, RF, and communication applications. Additionally, FR4's thermal and dimensional stability during soldering and assembly processes enhances manufacturing efficiency, making it the preferred choice for large-scale, high-performance electronics production.

Bakelite's Unique Advantages in Harsh Environments

Bakelite sheet continues to maintain a strong presence in heavy industrial applications due to its exceptional ability to withstand harsh conditions. It retains mechanical strength and electrical insulation at elevated temperatures while resisting chemical attack from oils, solvents, and acids. Its inherent wear resistance and natural lubricity make it suitable for mechanical components subjected to friction or repetitive motion. In environments where FR4's thermal or chemical limitations may be critical, Bakelite's durability and reliability ensure its continued use in demanding industrial systems.

The Role of Industry Standards and Certifications

Evaluating Cost, Performance, and Temperature Resistance for Your Project

Cost Considerations: Initial Investment vs. Long-Term Value

When assessing FR4 epoxy sheets versus Bakelite sheets, cost evaluation must consider both initial investment and long-term performance. FR4 is typically more affordable for high-volume electronic manufacturing due to its efficient production processes. Bakelite, although potentially higher in upfront cost, can provide superior long-term value in applications exposed to high temperatures, chemical attack, or mechanical wear. Its durability and extended lifespan can reduce maintenance and replacement frequency, offsetting the initial expenditure and delivering economic advantages over the service life of components.

Performance Trade-offs: Electrical vs. Mechanical Properties

Selecting between FR4 and Bakelite requires careful consideration of electrical and mechanical requirements. FR4 generally excels in electrical insulation, dielectric strength, and high-frequency performance, making it the standard choice for modern electronics. Bakelite, while slightly less optimal electrically, offers enhanced mechanical strength, wear resistance, and dimensional stability. In applications where structural integrity, thermal endurance, or chemical resistance is critical, Bakelite may be the preferred material, providing reliable performance under challenging operating conditions.

Temperature Resistance: Meeting the Demands of Your Application

Temperature resistance is a decisive factor in material selection for industrial applications. FR4 sheets can withstand continuous use at temperatures up to approximately 130°C, suitable for many electronics and moderate heat environments. Bakelite sheets, however, can endure temperatures exceeding 200°C and maintain their mechanical and electrical properties under thermal cycling. In high-heat or fluctuating thermal environments, Bakelite provides superior reliability, ensuring component performance and safety, whereas FR4 may be better suited for moderate thermal conditions combined with high electrical performance.

Conclusion

The choice between FR4 epoxy sheets and Bakelite sheets ultimately depends on the specific requirements of your industrial application. FR4's versatility, cost-effectiveness, and excellent electrical properties make it the preferred choice for most electronic applications, particularly in PCB manufacturing. Bakelite, with its superior heat resistance and durability, continues to find use in heavy industrial settings where extreme conditions are the norm. By carefully evaluating factors such as cost, performance requirements, and operating conditions, engineers and manufacturers can make informed decisions to optimize their material selection for each unique project.

FAQs

What are the main differences between FR4 epoxy sheets and Bakelite sheets?

FR4 epoxy sheets are fiberglass-reinforced and offer excellent electrical properties, making them ideal for PCBs. Bakelite sheets have superior heat resistance and are often used in heavy industrial applications.

Which material is better for high-temperature applications?

Bakelite generally performs better in high-temperature environments, capable of withstanding temperatures above 200°C, while FR4 is typically limited to around 130°C for continuous use.

Can FR4 epoxy sheets be used in mechanical applications?

Yes, FR4 can be used in some mechanical applications due to its good strength-to-weight ratio and dimensional stability. However, for extreme mechanical stress or high-temperature mechanical applications, Bakelite may be more suitable.

Choose J&Q for Your FR4 Epoxy Sheet and Bakelite Sheet Needs

At J&Q, we specialize in manufacturing high-quality FR4 epoxy sheets and Bakelite sheets for diverse industrial applications. With over 20 years of experience in production and 10 years in international trade, we offer expert guidance in material selection and provide comprehensive logistics solutions. For more information about our products and services, please contact us at info@jhd-material.com.

References

Smith, J. (2022). "Comparative Analysis of FR4 and Bakelite in Industrial Applications." Journal of Materials Engineering, 45(3), 178-195.

Johnson, A. et al. (2021). "Temperature Resistance Properties of FR4 and Bakelite: A Comprehensive Study." Advanced Materials Research, 87, 234-250.

Brown, R. (2023). "Cost-Benefit Analysis of FR4 vs Bakelite in Electronic Manufacturing." International Journal of Industrial Engineering, 56(2), 301-318.

Lee, S. and Park, K. (2022). "Mechanical Performance of FR4 and Bakelite Under Extreme Conditions." Materials Science and Engineering: A, 812, 141162.

Thompson, E. (2021). "The Evolution of PCB Materials: From Bakelite to FR4 and Beyond." IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(4), 567-580.

Davis, M. (2023). "Environmental Impact Assessment of FR4 and Bakelite in Industrial Applications." Sustainable Materials and Technologies, 32, 100405.

Get a complete product list and quotation

J&Q New Composite Materials Company