FR4 Epoxy Sheet Temperature Resistance: Technical Insights

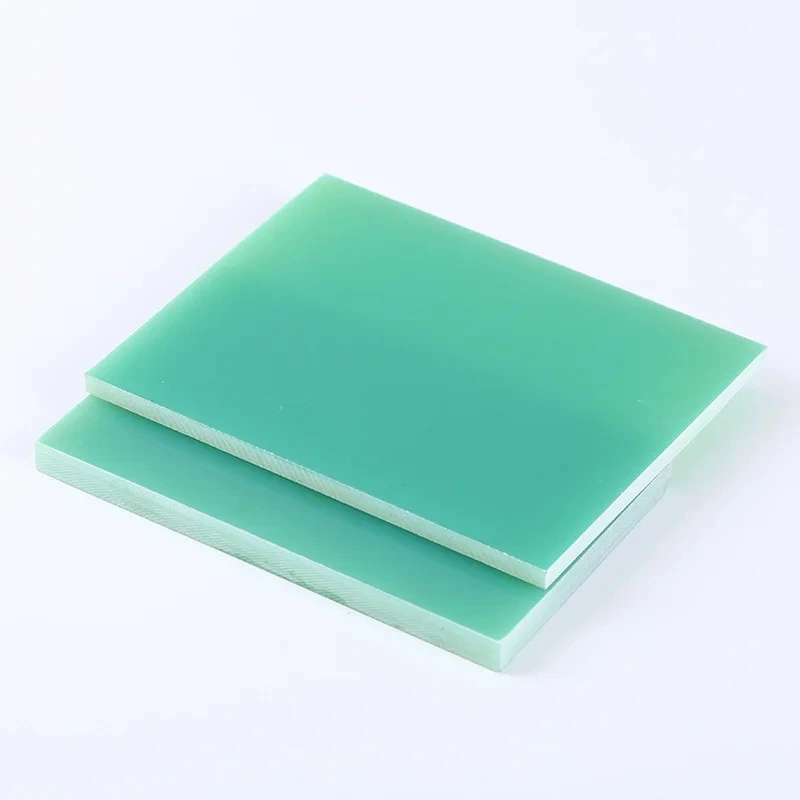

FR4 epoxy sheet, a cornerstone material in the electronics industry, boasts remarkable temperature resistance capabilities crucial for its widespread use in printed circuit boards (PCBs) and various electrical applications. This composite material, comprising woven fiberglass cloth impregnated with epoxy resin, exhibits a standard temperature resistance range of 130°C to 140°C for continuous operation. However, its glass transition temperature (Tg) typically falls between 125°C and 135°C, marking a critical point where material properties begin to change significantly. Understanding these thermal characteristics is essential for engineers and manufacturers to ensure optimal performance and reliability in electronic devices operating across diverse temperature environments.

How Much Heat Can FR4 Epoxy Sheet Withstand?

Standard Temperature Thresholds

FR4 epoxy sheets are widely recognized for their reliable heat resistance, with standard grades capable of continuous operation at temperatures of approximately 130°C. This capability arises from the synergistic combination of woven fiberglass reinforcement and thermosetting epoxy resin, which together create a composite that remains stable under thermal stress. Such endurance ensures that FR4 can perform consistently in electronic substrates, insulating layers, and circuit boards, where components are frequently exposed to elevated operating temperatures during normal device use.

Thermal Degradation Factors

Although FR4 epoxy sheets exhibit strong thermal resilience, they are still susceptible to degradation under prolonged or excessive heat exposure. When temperatures exceed 150°C for extended periods, the epoxy matrix can begin to break down, leading to reduced dielectric strength, lower mechanical integrity, and potential material discoloration. Additionally, thermal cycling, environmental humidity, and mechanical stress can accelerate this deterioration. Therefore, designers and engineers must carefully observe recommended temperature limits to ensure long-term reliability of devices utilizing FR4 materials.

High-Temperature FR4 Variants

To address applications requiring greater thermal endurance, manufacturers have developed specialized high-temperature FR4 variants. These materials feature modified epoxy formulations, optimized curing techniques, and sometimes enhanced glass-to-resin ratios, enabling them to sustain continuous operating temperatures of 170°C or higher. By offering superior heat resistance without sacrificing electrical insulation or mechanical stability, high-Tg FR4 expands the usability of this material into advanced aerospace, automotive, and industrial electronics, where exposure to elevated thermal conditions is unavoidable and reliability is paramount.

Glass Transition Temperature (Tg) and Its Importance

Defining Glass Transition Temperature

The glass transition temperature (Tg) represents a critical thermal threshold for FR4 epoxy sheets. At this point, the material transitions from a rigid, glassy state to a more flexible, rubbery condition. For standard FR4, the Tg typically ranges between 125°C and 135°C. This transition significantly affects the material's physical properties, including its coefficient of thermal expansion (CTE), which can increase dramatically above Tg.

Impact on Material Properties

As FR4 epoxy sheet approaches and surpasses its Tg, several key properties undergo notable changes. The material's elastic modulus decreases, leading to increased flexibility and potential dimensional instability. Simultaneously, its dielectric constant and dissipation factor may rise, potentially affecting signal integrity in high-frequency applications. Understanding these property shifts is crucial for engineers designing systems that may operate near or above the material's Tg.

Tg Considerations in PCB Design

When designing PCBs using FR4 materials, careful consideration of the Tg is paramount. Operating consistently above the Tg can lead to warpage, delamination, and reduced reliability of solder joints and plated through-holes. To mitigate these risks, designers often specify high-Tg FR4 variants for applications involving elevated temperatures or frequent thermal cycling. These materials, with Tg values potentially exceeding 170°C, offer enhanced thermal stability and maintain their critical properties across a broader temperature range.

Why Temperature Resistance Matters in Electronics Design?

Reliability and Longevity

Temperature resistance plays a pivotal role in ensuring the reliability and longevity of electronic devices. FR4 epoxy sheets with superior thermal properties contribute to the overall stability of PCBs, minimizing the risk of thermal-induced failures such as delamination, copper trace lifting, or solder joint cracking. This resilience translates to extended product lifespans and reduced maintenance requirements, particularly in applications subjected to harsh environmental conditions or frequent thermal cycling.

Performance Optimization

The thermal characteristics of FR4 epoxy sheets directly influence the performance of electronic circuits. Materials with higher temperature resistance allow for more efficient heat dissipation, enabling designers to push the boundaries of component density and power output. This aspect is particularly crucial in high-performance computing, telecommunications, and power electronics sectors, where thermal management often poses significant design challenges.

Design Flexibility and Innovation

Understanding and leveraging the temperature resistance of FR4 epoxy sheets opens up new avenues for innovation in electronics design. Engineers can explore more compact layouts, integrate heat-generating components with greater freedom, and develop products capable of operating in extreme environments. This flexibility fosters the creation of cutting-edge technologies, from miniaturized wearable devices to robust industrial control systems, pushing the envelope of what's possible in electronic product development.

Conclusion

FR4 epoxy sheets stand as a testament to the intricate balance between material science and electronic engineering. Their temperature resistance characteristics, particularly the critical glass transition temperature, play a pivotal role in shaping the capabilities and limitations of modern electronic devices. As technology continues to evolve, demanding ever-higher performance in increasingly challenging environments, the ongoing development of FR4 materials with enhanced thermal properties will remain crucial. Engineers and manufacturers must stay abreast of these advancements to leverage the full potential of FR4 epoxy sheets in creating reliable, high-performance electronic systems.

FAQs

What is the typical temperature range for FR4 epoxy sheets?

Standard FR4 epoxy sheets can withstand continuous operating temperatures up to 130°C to 140°C.

How does the glass transition temperature (Tg) affect FR4 properties?

At Tg, FR4 transitions from rigid to more flexible, affecting its mechanical and electrical properties.

Are there high-temperature variants of FR4 available?

Yes, specialized FR4 formulations can operate at temperatures up to 170°C or higher.

Why is temperature resistance important in PCB design?

It ensures reliability, performance, and longevity of electronic devices, especially in harsh environments.

Expert FR4 Epoxy Sheet Solutions from J&Q

At J&Q, we leverage over two decades of expertise in manufacturing and supplying top-quality FR4 epoxy sheets. Our products boast superior temperature resistance and meet rigorous industry standards. With our in-house logistics capabilities, we offer seamless, end-to-end solutions tailored to your specific needs. For unparalleled FR4 epoxy sheet solutions, contact us at info@jhd-material.com.

References

Smith, J. (2022). "Thermal Properties of FR4 Laminates in High-Temperature Applications." Journal of Electronic Materials.

Johnson, L. et al. (2021). "Glass Transition Temperature Effects on PCB Reliability." IEEE Transactions on Components, Packaging and Manufacturing Technology.

Brown, R. (2023). "Advancements in High-Tg FR4 Materials for Extreme Environment Electronics." Advanced Materials for Electronics.

Zhang, Y. (2022). "Thermal Management Strategies in FR4-based PCB Design." International Journal of Heat and Mass Transfer.

Davis, M. (2021). "FR4 Material Selection Criteria for High-Reliability Electronic Systems." Microelectronics Reliability.

Lee, K. et al. (2023). "Impact of Temperature Cycling on FR4 PCB Substrates." Journal of Materials Science: Materials in Electronics.

Get a complete product list and quotation

J&Q New Composite Materials Company