What Determines the Mechanical Strength of FR4?

Composition and Manufacturing Process

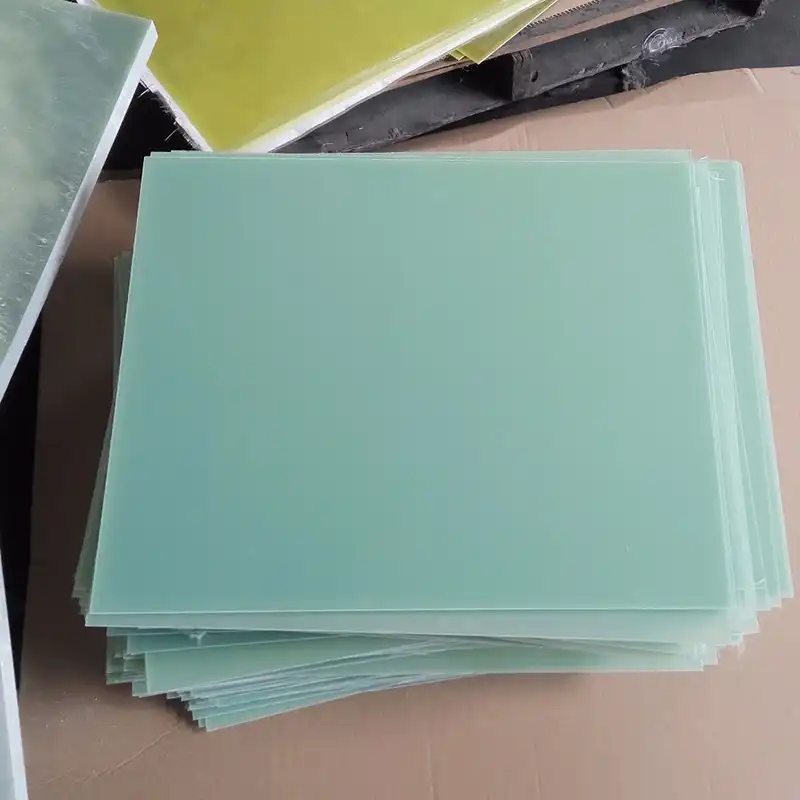

The mechanical strength of FR4 epoxy sheet is primarily determined by its composition and manufacturing process. The core material consists of woven fiberglass cloth, which provides the foundation for its robust structure. This fiberglass is then impregnated with epoxy resin, creating a composite that combines the strength of glass fibers with the binding and insulating properties of epoxy. The manufacturing process involves carefully layering these materials and subjecting them to heat and pressure, resulting in a dense, uniform structure.

Fiberglass Reinforcement

The fiberglass component plays a crucial role in enhancing the mechanical strength of FR4 sheets. The glass fibers, typically E-glass, are arranged in a woven pattern that distributes stress evenly across the material. This arrangement significantly contributes to the sheet's ability to resist deformation under load, providing excellent tensile strength and dimensional stability. The orientation and density of these fibers can be adjusted during manufacturing to optimize the mechanical properties for specific applications.

Epoxy Resin Quality

The quality and type of epoxy resin used in FR4 sheets greatly influence their overall mechanical performance. High-grade epoxy resins offer superior bonding strength, ensuring that the fiberglass layers are tightly held together. This strong inter-layer adhesion is essential for preventing delamination and enhancing the material's resistance to impact and flexural stress. Additionally, advanced epoxy formulations can improve the sheet's resistance to environmental factors such as moisture and chemicals, further contributing to its long-term durability.

Tensile, Flexural, and Impact Resistance Properties

Tensile Strength Analysis

FR4 epoxy sheets exhibit impressive tensile strength, typically ranging from 280 to 320 MPa. This high tensile strength enables the material to withstand significant pulling forces without breaking or deforming. The alignment of glass fibers within the epoxy matrix allows for efficient load distribution, enhancing the material's ability to resist elongation under tension. This property is particularly valuable in applications where the material may be subjected to continuous or cyclical tensile loads, such as in structural components or high-stress electronic assemblies.

Flexural Rigidity and Elasticity

The flexural strength of FR4 epoxy sheets is another noteworthy characteristic, usually falling between 340 and 380 MPa. This high flexural strength indicates the material's exceptional resistance to bending forces. The combination of rigid glass fibers and flexible epoxy resin creates a composite that can withstand substantial flexural stress without permanent deformation. This property is crucial in applications where the material may experience bending loads, such as in printed circuit boards or structural panels in aerospace components.

Impact Resistance Capabilities

FR4 epoxy sheets demonstrate remarkable impact resistance, a critical property for materials used in environments prone to sudden shocks or impacts. The impact strength of FR4 is typically measured using methods like the Izod impact test, with values often exceeding 800 J/m. This high impact resistance is attributed to the material's ability to absorb and dissipate energy through its composite structure. The fiberglass reinforcement helps distribute the impact force across a larger area, while the epoxy matrix provides some degree of elasticity to absorb the shock without catastrophic failure.

Longevity and Performance in Mechanical Stress Applications

Long-term Stability Under Mechanical Load

FR4 epoxy sheets excel in maintaining their mechanical properties over extended periods, even when subjected to continuous mechanical stress. This long-term stability is crucial for applications in industries such as aerospace and telecommunications, where components must maintain their integrity for years without significant degradation. The material's resistance to creep - the tendency to deform slowly under persistent stress - is particularly noteworthy. This resistance to creep ensures that FR4 components maintain their dimensional accuracy and structural integrity, even in applications involving constant mechanical loads.

Environmental Resistance and Durability

The durability of FR4 epoxy sheets extends beyond mere mechanical strength, encompassing excellent resistance to various environmental factors. These sheets demonstrate remarkable stability in the face of temperature fluctuations, maintaining their mechanical properties across a wide temperature range, typically from -65°C to 125°C. Additionally, FR4's low moisture absorption rate (typically less than 0.1% after 24 hours of immersion) contributes significantly to its long-term performance, especially in humid or moisture-prone environments. This combination of thermal stability and moisture resistance ensures that FR4 components remain structurally sound and dimensionally stable under diverse environmental conditions.

Fatigue Resistance and Cyclic Loading

FR4 epoxy sheets exhibit exceptional fatigue resistance, a critical property for components subjected to repetitive or cyclic loading. This resistance to fatigue is particularly important in applications such as vibration-prone environments or in components that undergo frequent thermal cycling. The material's ability to withstand repeated stress without significant degradation in mechanical properties is attributed to its composite structure. The fiberglass reinforcement helps distribute stress evenly, while the epoxy matrix provides flexibility to absorb and dissipate cyclic loads. This characteristic makes FR4 an ideal choice for applications requiring long-term reliability under dynamic mechanical stresses.

Conclusion

FR4 epoxy sheets stand as a paragon of mechanical strength and durability in the realm of composite materials. Their exceptional tensile, flexural, and impact resistance properties, coupled with long-term stability under various environmental and mechanical stresses, make them an invaluable material across numerous industries. The unique combination of fiberglass reinforcement and high-quality epoxy resin results in a material that not only meets stringent performance requirements but also ensures reliability and longevity in demanding applications. As technology advances, FR4 continues to prove its worth as a versatile and robust material, adaptable to evolving engineering challenges.

Contact Us

For more information about our FR4 epoxy sheets and their applications, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your mechanical and electrical insulation needs.