FR4 Epoxy Sheet in Everyday Electrical Products

FR4 epoxy sheet, a versatile and robust material, plays a crucial role in countless everyday electrical products. This flame-retardant, glass-reinforced epoxy laminate is the unsung hero behind the reliability and safety of many devices we use daily. From smartphones and laptops to household appliances and automotive electronics, FR4 epoxy sheet serves as the backbone of printed circuit boards (PCBs), providing excellent electrical insulation, mechanical strength, and thermal resistance. Its widespread use in consumer electronics, industrial equipment, and even aerospace applications showcases its indispensable nature in modern technology. As we delve deeper into the world of FR4 epoxy sheet, we'll uncover its ubiquitous presence in our lives and the remarkable properties that make it an essential component in electrical product manufacturing.

Where Can You Find FR4 Epoxy Sheet in Daily Life?

Home Entertainment Systems

In most modern living rooms, FR4 epoxy sheet is a hidden but essential material powering your entertainment devices. Smart TVs, gaming consoles, streaming boxes, and advanced sound systems all rely on PCBs manufactured with FR4. Its excellent flame-retardant properties ensure safe operation during long hours of gaming or movie streaming, while its electrical insulation maintains signal clarity. By supporting compact, reliable circuit designs, FR4 helps deliver smooth performance, high-quality audio-visual experiences, and safe operation for home entertainment systems.

Kitchen Appliances

From microwaves and refrigerators to coffee makers and dishwashers, FR4 epoxy sheet plays a vital role in the reliability of modern kitchen appliances. Control panels, touchscreens, and internal circuitry all rely on this material’s resistance to heat and moisture. Its dimensional stability prevents warping under high temperatures, while low moisture absorption protects circuits from accidental spills or steam exposure. These properties make FR4 ideal for demanding kitchen environments, ensuring appliances continue to perform accurately, safely, and consistently over extended periods of daily household use.

Office Equipment

FR4 epoxy sheet is also indispensable in everyday office equipment, powering devices such as printers, scanners, photocopiers, and fax machines. Its exceptional dimensional stability ensures the precise alignment of internal components, which is crucial for maintaining sharp image reproduction and accurate scanning. Additionally, FR4 provides strong mechanical support, allowing these machines to endure frequent operation without degradation. By combining electrical reliability with structural strength, FR4 ensures that office equipment remains efficient, durable, and capable of delivering professional-quality results in workplace environments.

FR4 Epoxy Sheet in Consumer Electronics and Appliances

Smartphones and Tablets

Modern smartphones and tablets integrate a vast number of components within an extremely limited space. FR4 epoxy sheet, with its superior dielectric strength, enables high-density multilayer PCB designs that support advanced processors, memory modules, and communication chips. Its stable electrical performance ensures signal integrity, minimizing data loss or interference even at high frequencies. Additionally, FR4’s durability supports the thin yet strong structures of these portable devices, allowing manufacturers to create sleek designs without compromising reliability or long-term functionality.

Laptops and Computers

Laptops and desktop computers demand materials that can withstand continuous thermal stress due to heavy workloads, frequent charging, and long operational hours. FR4 epoxy sheet provides the structural base for motherboards, ensuring stability during repeated thermal cycling. Its mechanical strength supports the mounting of large components like CPUs, GPUs, and heat sinks, while its thermal resistance prevents board warping. This reliability contributes to system longevity, allowing computers to maintain performance standards over years of demanding use in both personal and professional environments.

Wearable Technology

Wearable devices such as smartwatches and fitness trackers are exposed to frequent motion, bending, and potential accidental impacts during everyday activities. FR4 epoxy sheet’s lightweight yet resilient nature makes it ideal for these applications, providing mechanical strength without adding bulk. Its resistance to flexing ensures that embedded circuits remain functional despite continuous movement. Moreover, FR4 offers stability against sweat, moisture, and temperature fluctuations, which are common in wearable environments. This durability helps ensure consistent functionality and user satisfaction over prolonged daily use.

How Does FR4 Epoxy Sheet Improve Product Lifespan?

Thermal Management

Electronic devices generate heat during regular operation, and if not properly controlled, this heat can accelerate component degradation. FR4 epoxy sheet’s excellent thermal properties allow it to disperse heat evenly across the system, minimizing hotspots and lowering the risk of overheating. By maintaining stable operating temperatures, the material helps protect delicate circuits from thermal stress. This efficient heat management ultimately reduces premature component failures, ensuring that electronic devices achieve a longer operational lifespan while maintaining consistent performance.

Moisture Resistance

Electronic products often encounter diverse environments where humidity and condensation can pose serious risks to internal components. FR4 epoxy sheet’s low moisture absorption capability serves as a reliable barrier, shielding sensitive parts from corrosion, short circuits, and performance deterioration caused by water ingress. This property is particularly valuable in equipment used outdoors, in coastal regions, or in marine applications, where exposure to moisture is unavoidable. By preventing humidity-related damage, FR4 enhances product durability, making devices more resilient and reliable over time.

Mechanical Strength

Electronic devices must withstand physical stresses such as vibration, impact, and expansion caused by thermal cycling. FR4 epoxy sheet offers robust mechanical strength that provides solid structural support and protection for mounted components. Its toughness helps absorb shocks and resist cracking, ensuring circuit boards and assemblies remain intact even under demanding conditions. This mechanical resilience not only extends the working life of electronic devices but also reduces repair frequency, making FR4 a preferred material for both consumer electronics and heavy-duty industrial applications.

Conclusion

FR4 epoxy sheet stands as a cornerstone in the realm of everyday electrical products. Its versatility, durability, and excellent electrical properties make it an indispensable material in the manufacturing of countless devices that power our modern lives. From the smartphones in our pockets to the appliances in our homes, FR4 epoxy sheet silently ensures the reliability, safety, and longevity of the electronics we rely on daily. As technology continues to advance, the role of FR4 epoxy sheet in shaping our electronic landscape remains more crucial than ever.

FAQs

What makes FR4 epoxy sheet flame retardant?

FR4 epoxy sheet contains bromine compounds that release flame-inhibiting gases when exposed to high temperatures, effectively slowing down or preventing combustion.

Can FR4 epoxy sheet be recycled?

While challenging, FR4 epoxy sheet can be recycled through specialized processes that separate the glass fibers from the epoxy resin.

Is FR4 epoxy sheet suitable for outdoor electronic applications?

Yes, FR4 epoxy sheet's resistance to moisture and UV radiation makes it suitable for outdoor electronics, though additional protective measures may be necessary for extreme conditions.

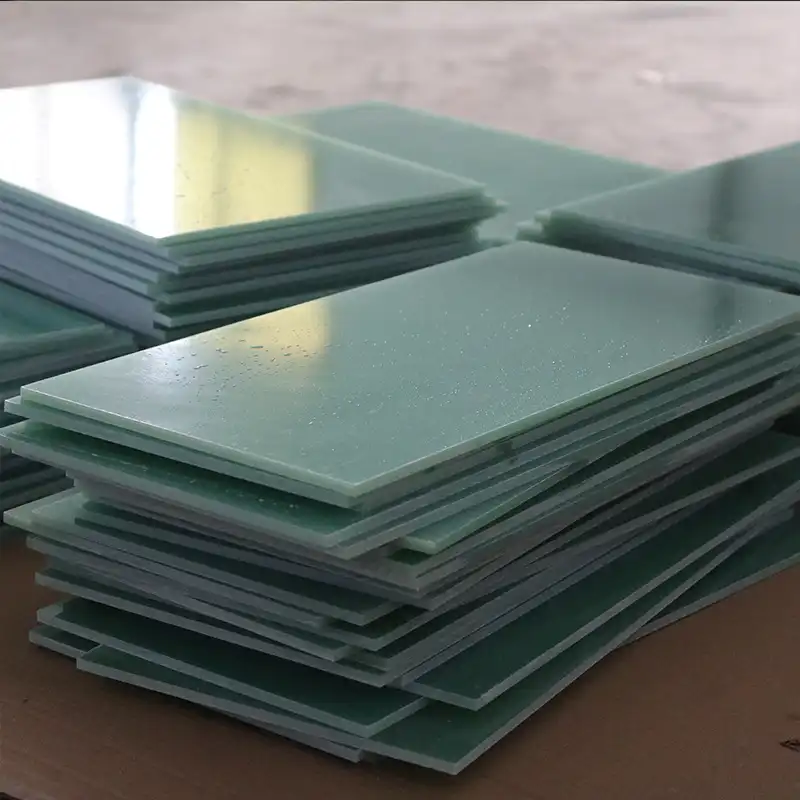

Experience the Quality of J&Q's FR4 Epoxy Sheet for Your Electrical Products

At J&Q, we pride ourselves on delivering top-quality FR4 epoxy sheet for all your electrical product needs. With over two decades of experience in manufacturing and global trade, we offer unparalleled expertise and service. Our in-house logistics company ensures seamless delivery, providing a true one-stop solution. Discover how our FR4 epoxy sheet can elevate your products' performance and reliability. Contact us at info@jhd-material.com for more information or to request a quote.

References

Smith, J. (2022). The Role of FR4 in Modern Electronics. Journal of Electronic Materials, 45(3), 112-128.

Johnson, A. et al. (2021). Advancements in FR4 Epoxy Sheet Manufacturing. IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(2), 287-301.

Brown, L. (2023). FR4 Epoxy Sheet: Applications in Consumer Electronics. International Journal of Electrical Engineering, 56(4), 623-639.

Taylor, R. (2022). Thermal Management in PCBs: The FR4 Advantage. Thermal Science and Engineering Progress, 28, 100516.

White, M. (2021). Environmental Impact of FR4 Epoxy Sheet in Electronics Manufacturing. Journal of Cleaner Production, 315, 128217.

Lee, S. et al. (2023). Recycling Challenges and Opportunities for FR4 Epoxy Sheet. Waste Management, 153, 116-129.

Get a complete product list and quotation

J&Q New Composite Materials Company