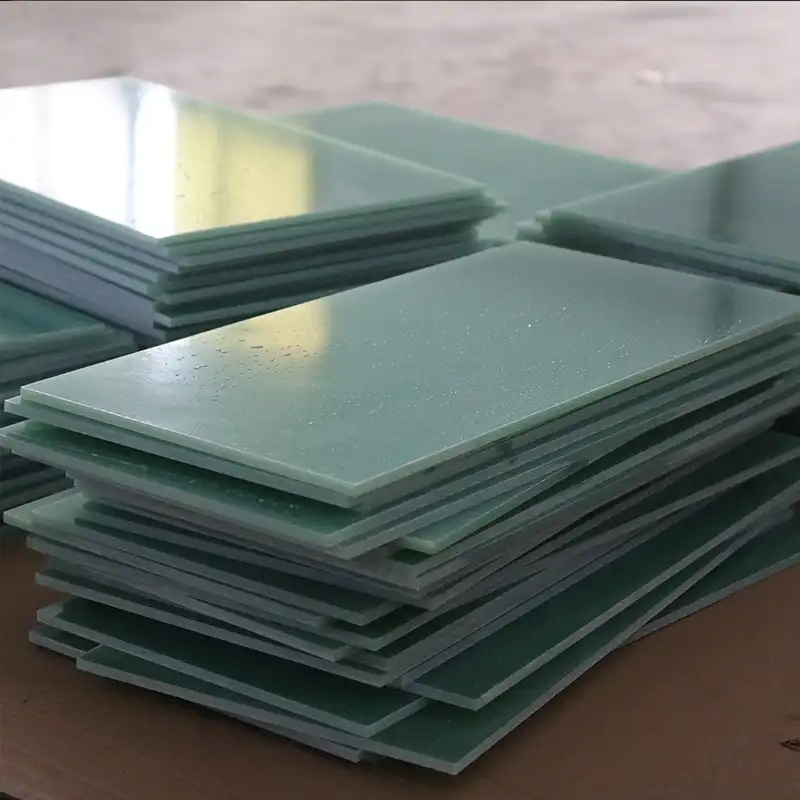

Dielectric Properties of FR4 Epoxy Sheets

Understanding Dielectric Constant

The dielectric constant, also known as relative permittivity, is a crucial parameter in evaluating the electrical properties of FR4 epoxy sheets. It measures the material's ability to store electrical energy in an electric field. FR4 epoxy sheets typically have a dielectric constant ranging from 4.2 to 4.8, depending on the specific formulation and manufacturing process. This relatively low dielectric constant contributes to the material's excellent insulating properties, making it suitable for high-frequency applications.

Factors Affecting Dielectric Constant

Several factors can influence the dielectric constant of FR4 epoxy sheets. The resin content, glass fiber reinforcement, and curing process all play a role in determining the final dielectric properties. Additionally, environmental factors such as temperature and humidity can impact the dielectric constant. Manufacturers often fine-tune these parameters to achieve specific dielectric characteristics for different applications.

Dielectric Loss Tangent

Another important dielectric property of FR4 epoxy sheets is the dielectric loss tangent. This parameter quantifies the amount of electromagnetic energy dissipated as heat within the material. FR4 epoxy boards typically exhibit low dielectric loss, which is advantageous for high-frequency applications where signal integrity is paramount. The low dielectric loss tangent helps minimize signal attenuation and distortion, ensuring reliable performance in electronic circuits.

Material Characteristics of FR4 Epoxy Sheets

Mechanical Strength and Durability

FR4 epoxy sheets are renowned for their exceptional mechanical strength and durability. The combination of woven fiberglass reinforcement and epoxy resin creates a robust composite material capable of withstanding various mechanical stresses. This high strength-to-weight ratio makes FR4 epoxy boards ideal for applications requiring structural integrity alongside electrical insulation properties. The material's resistance to flexing, bending, and impact contributes to its longevity and reliability in demanding environments.

Thermal Properties

One of the standout characteristics of FR4 epoxy sheets is their excellent thermal properties. These materials exhibit a high glass transition temperature (Tg), typically ranging from 130°C to 180°C, depending on the specific formulation. This high Tg allows FR4 epoxy boards to maintain their mechanical and electrical properties even at elevated temperatures. Additionally, FR4 epoxy sheets have low thermal expansion coefficients, minimizing dimensional changes during temperature fluctuations. These thermal characteristics make FR4 epoxy sheets suitable for applications involving thermal cycling and high-temperature environments.

Chemical Resistance

FR4 epoxy sheets demonstrate remarkable chemical resistance, making them suitable for use in diverse environments. The epoxy resin matrix provides excellent protection against a wide range of chemicals, including acids, alkalis, and organic solvents. This chemical resistance ensures the longevity and reliability of FR4 epoxy boards in various industrial and electronic applications. However, it's essential to consider the specific chemical exposure conditions and consult manufacturer guidelines for optimal material selection.

Applications and Advantages of FR4 Epoxy Sheets

Printed Circuit Board Manufacturing

The primary application of FR4 epoxy sheets is in the production of printed circuit boards (PCBs). The material's combination of excellent dielectric properties, mechanical strength, and thermal stability makes it ideal for creating reliable and high-performance PCBs. FR4 epoxy boards serve as the substrate for mounting electronic components and creating conductive tracks. The material's low dielectric constant and loss tangent contribute to improved signal integrity, especially in high-frequency applications.

Aerospace and Defense Industries

FR4 epoxy sheets find extensive use in aerospace and defense applications due to their exceptional mechanical and electrical properties. The material's high strength-to-weight ratio, combined with its excellent dielectric characteristics, makes it suitable for avionics systems, radar equipment, and communication devices. FR4 epoxy boards can withstand the harsh environmental conditions encountered in aerospace applications, including temperature extremes and vibrations.

Emerging Technologies and Future Prospects

As technology continues to advance, FR4 epoxy sheets are finding new applications in emerging fields. The material's versatility makes it suitable for use in 5G telecommunications infrastructure, Internet of Things (IoT) devices, and wearable electronics. Ongoing research and development efforts aim to further enhance the dielectric properties and material characteristics of FR4 epoxy sheets, expanding their potential applications in cutting-edge technologies.

Conclusion

FR4 epoxy sheets stand out as a versatile and reliable material for electronic applications, thanks to their exceptional dielectric constant and material characteristics. Their low dielectric constant, high mechanical strength, and excellent thermal properties make them ideal for printed circuit board manufacturing and various other industries. As technology continues to evolve, FR4 epoxy boards remain at the forefront of electronic material innovation, adapting to meet the demands of emerging technologies and pushing the boundaries of what's possible in electronic design and manufacturing.

Contact Us

For more information about our FR4 epoxy sheets and how they can benefit your projects, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.