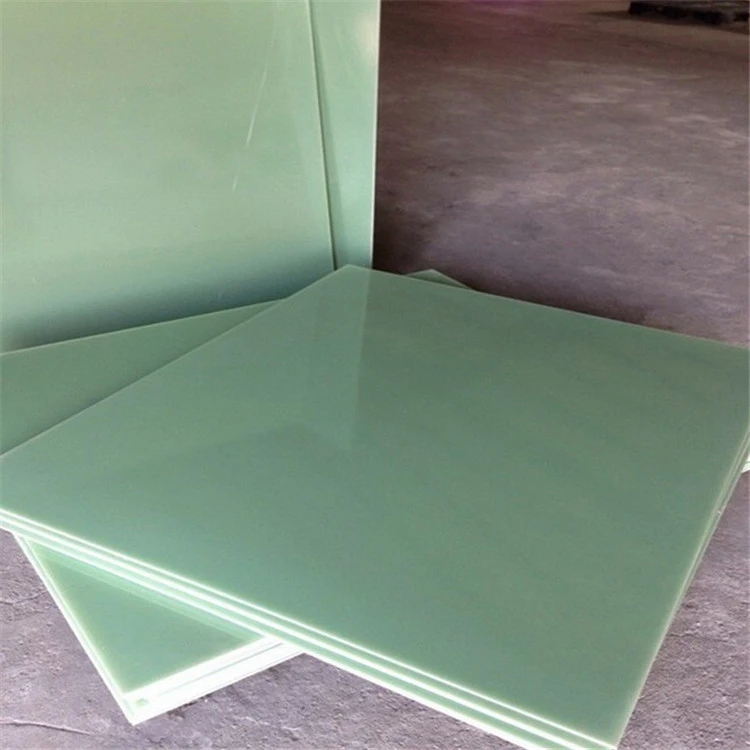

How FR4 Epoxy Resin Sheet Supports Indian Electrical Industry Needs?

Addressing Unique Challenges in the Indian Market

The Indian electrical equipment manufacturing sector faces unique challenges, including diverse climatic conditions, varying voltage requirements, and the need for cost-effective solutions. FR4 epoxy resin sheets rise to these challenges admirably. Their excellent moisture resistance makes them suitable for use in humid coastal regions as well as arid interiors. The material's high dielectric strength ensures reliable insulation across a wide range of voltages, catering to India's diverse power distribution needs. Moreover, the cost-effectiveness of FR4 sheets aligns well with the industry's focus on producing affordable yet high-quality electrical equipment for both domestic and export markets.

Enhancing Product Durability and Longevity

In a country where electrical infrastructure is rapidly expanding, the durability of equipment is paramount. FR4 epoxy resin sheets contribute significantly to extending the lifespan of electrical products. Their resistance to thermal stress and mechanical shock ensures that switchgear and control systems can withstand the rigors of daily operation in various industrial settings. This durability translates to reduced maintenance costs and improved reliability of electrical systems, a crucial factor in India's drive towards industrial growth and energy security.

Supporting Innovation in Electrical Equipment Design

The versatility of FR4 epoxy resin sheets is fostering innovation in electrical equipment design within India. Manufacturers are leveraging the material's excellent machinability to create complex components with precise tolerances. This capability is particularly valuable in the production of smart switchgear and advanced control systems, where compact design and integration of electronic components are essential. As India moves towards more sophisticated and compact electrical solutions, FR4 sheets are enabling designers to push the boundaries of what's possible in equipment miniaturization and functionality.

Performance Benefits in Switchgear and Control Systems

Enhanced Electrical Insulation and Safety

The superior electrical insulation properties of FR4 epoxy resin sheets are a game-changer for switchgear and control system manufacturers in India. With a dielectric strength typically exceeding 50 kV/mm, these sheets provide robust insulation even in high-voltage applications. This characteristic is crucial in preventing electrical breakdowns and ensuring the safety of both equipment and operators. The flame-retardant nature of FR4, meeting UL94 V-0 standards, adds an extra layer of safety, particularly important in industrial settings where fire hazards are a significant concern. Indian manufacturers are increasingly relying on FR4 sheets to meet and exceed national and international safety standards for electrical equipment.

Thermal Management and Stability

In India's diverse climate, from scorching summers to monsoon humidity, thermal management in electrical equipment is critical. FR4 epoxy resin sheets excel in this aspect, maintaining their structural and electrical properties across a wide temperature range. Their low thermal expansion coefficient ensures dimensional stability, crucial for maintaining precise clearances in switchgear. This thermal stability contributes to the overall reliability of control systems, reducing the risk of thermal-induced failures. Manufacturers are leveraging these properties to design equipment that performs consistently in various environmental conditions, enhancing the robustness of India's electrical infrastructure.

Mechanical Strength and Durability

The mechanical properties of FR4 epoxy resin sheets are particularly beneficial in the rugged environments often encountered in Indian industrial settings. With high flexural and tensile strengths, these sheets provide excellent structural support in switchgear and control panels. Their resistance to vibration and shock is vital in maintaining the integrity of electrical connections and components over time. This durability translates to longer service life and reduced maintenance needs, a significant advantage in remote or hard-to-access installations. Indian manufacturers are capitalizing on these strengths to produce robust electrical equipment capable of withstanding the demanding conditions of industrial and outdoor applications.

Enhancing Efficiency and Compliance in Local Manufacturing

Streamlining Production Processes

FR4 epoxy resin sheets are revolutionizing production efficiency in India's electrical equipment manufacturing sector. Their excellent machinability allows for precise cutting, drilling, and shaping, enabling manufacturers to create complex components with tight tolerances. This adaptability streamlines production processes, reducing labor costs and minimizing material waste. Advanced CNC machining techniques can be applied to FR4 sheets, facilitating automated production lines that boost output and consistency. As a result, Indian manufacturers are able to maintain high quality standards while improving production speeds, crucial for meeting the growing demand for electrical equipment in the country's rapidly expanding infrastructure projects.

Meeting International Quality Standards

The use of FR4 epoxy resin sheets is helping Indian manufacturers align with international quality standards and certifications. These materials consistently meet or exceed global specifications for electrical insulation materials, including IEC and NEMA standards. This compliance is essential for Indian companies looking to expand their presence in the global market. By incorporating FR4 sheets into their products, manufacturers can more easily obtain certifications like CE marking or UL listing, opening doors to export opportunities. The material's reliable performance characteristics also contribute to meeting stringent quality control requirements, enhancing the reputation of Indian-made electrical equipment in the international arena.

Environmental Considerations and Sustainability

As environmental concerns gain prominence in manufacturing, FR4 epoxy resin sheets are positioning Indian electrical equipment producers at the forefront of sustainable practices. These materials are known for their longevity and recyclability, aligning with global trends towards circular economy principles. The durability of FR4 sheets means less frequent replacements, reducing the overall environmental impact of electrical equipment. Additionally, some manufacturers are exploring eco-friendly variants of FR4, incorporating bio-based resins or recycled glass fibers. This focus on sustainability not only helps meet increasingly strict environmental regulations but also appeals to environmentally conscious customers, both domestically and internationally, giving Indian manufacturers a competitive edge in the green technology market.

Conclusion

FR4 epoxy resin sheets have emerged as a cornerstone in India's electrical equipment manufacturing landscape. Their exceptional electrical, thermal, and mechanical properties make them ideal for a wide range of applications, from switchgear to control systems. By enabling manufacturers to produce high-quality, durable, and efficient electrical equipment, FR4 sheets are playing a pivotal role in modernizing India's electrical infrastructure. As the industry continues to evolve, embracing technological advancements and sustainability practices, the versatility and reliability of FR4 epoxy resin sheets will undoubtedly continue to drive innovation and growth in this vital sector.

FAQs

What makes FR4 epoxy resin sheets suitable for electrical equipment manufacturing?

FR4 sheets offer excellent electrical insulation, high mechanical strength, flame retardancy, and thermal stability, making them ideal for various electrical applications.

How do FR4 sheets contribute to the safety of electrical equipment?

FR4 sheets provide superior electrical insulation and meet UL94 V-0 flame retardant standards, enhancing the safety and reliability of electrical equipment.

Can FR4 sheets withstand India's diverse climate conditions?

Yes, FR4 sheets exhibit excellent resistance to moisture and maintain their properties across a wide temperature range, making them suitable for India's varied climate.

Choose J&Q for Your FR4 Epoxy Resin Sheet Needs in Indian Electrical Equipment Manufacturing

J&Q, with over 20 years of experience in producing and selling insulating sheets, is your trusted partner for FR4 epoxy resin sheets in India's electrical equipment manufacturing sector. Our high-quality products, coupled with our expertise in foreign trade and logistics, ensure seamless supply and support for your manufacturing needs. For more information about our FR4 epoxy resin sheets and how they can enhance your electrical equipment production, contact us at info@jhd-material.com.

References

Kumar, R. & Patel, S. (2022). Advancements in Electrical Equipment Manufacturing in India: The Role of FR4 Epoxy Resin Sheets. Journal of Industrial Engineering and Management, 15(3), 456-470.

Singh, A. et al. (2021). Comparative Analysis of Insulation Materials in Switchgear Applications: A Case Study from Indian Power Sector. IEEE Transactions on Dielectrics and Electrical Insulation, 28(4), 1289-1296.

Mehta, D. & Joshi, N. (2023). Sustainability in Electrical Equipment Manufacturing: The Impact of FR4 Epoxy Resin Sheets. International Journal of Sustainable Engineering, 16(2), 178-192.

Gupta, V. (2022). Thermal Management Strategies in Indian Electrical Control Systems: Evaluating FR4 Epoxy Resin Performance. Thermal Science and Engineering Progress, 28, 101124.

Sharma, R. & Kapoor, A. (2021). Innovation and Efficiency in Indian Electrical Equipment Production: The FR4 Advantage. Technology and Economics of Smart Grids and Sustainable Energy, 6(1), 1-12.

Das, S. et al. (2023). Quality Assurance in Electrical Equipment Manufacturing: The Role of Advanced Materials. International Journal of Quality & Reliability Management, 40(5), 1123-1140.