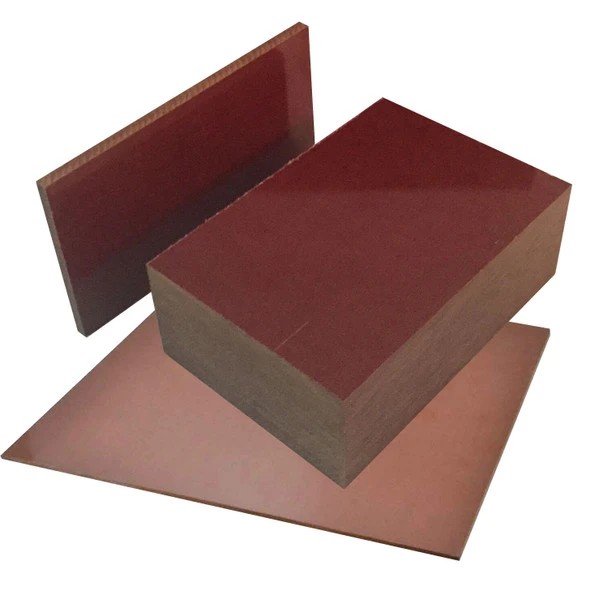

Custom Thickness Phenolic Sheets for Global Supply

Custom thickness phenolic resin sheets are versatile insulating materials tailored to meet specific industrial requirements worldwide. These sheets, manufactured through precision processes, offer unparalleled electrical and mechanical properties. By adjusting the thickness during production, manufacturers can create phenolic resin sheets that perfectly align with diverse applications across various sectors. From electrical insulation in power distribution systems to mechanical components in aerospace, custom thickness phenolic resin sheets provide the flexibility and performance needed to meet global demand. Their adaptability, combined with superior insulation properties, makes them indispensable in today's rapidly evolving industrial landscape.

How Are Custom Phenolic Sheets Manufactured to Spec?

Raw Material Selection and Preparation

The manufacturing process of custom phenolic sheets begins with careful selection of raw materials. High-quality phenolic resins are combined with reinforcing materials such as paper, cotton, or glass fibers. The choice of reinforcement depends on the desired properties of the final product. These materials are carefully prepared and mixed to ensure uniformity and consistency in the finished sheets.

Impregnation and Layering Process

Once the materials are prepared, the reinforcing substrate is impregnated with the phenolic resin to create the phenolic resin sheet. This process ensures that the resin thoroughly penetrates the reinforcing material, creating a strong, cohesive structure. Multiple layers of the impregnated material are then stacked to achieve the desired thickness. The number of layers and their arrangement can be adjusted to meet specific customer requirements.

Heat and Pressure Application

The stacked layers undergo a carefully controlled curing process involving heat and pressure. This stage is crucial in determining the final properties of the phenolic sheets. The application of heat activates the resin, causing it to flow and bond with the reinforcing material. Simultaneously, pressure is applied to remove any air pockets and ensure uniform density throughout the sheet. The precise control of temperature and pressure allows manufacturers to create sheets with custom thicknesses and specific mechanical properties.

Thickness Options and Tolerances for Industrial Applications

Standard Thickness Range

Phenolic resin sheets are available in a wide range of thicknesses to cater to diverse industrial needs. Standard thickness options typically range from 0.5 mm to 50 mm, with increments as small as 0.1 mm. This extensive range allows for precise customization to meet specific application requirements. Thinner sheets are often used in applications requiring flexibility or where space is limited, while thicker sheets provide enhanced structural integrity and insulation properties.

Custom Thickness Capabilities

Beyond standard offerings, many manufacturers have the capability to produce phenolic sheets with custom thicknesses. This flexibility is particularly valuable for specialized applications that require non-standard dimensions. Custom thicknesses can be achieved through adjustments in the layering process or by precision machining of standard sheets. The ability to produce sheets with exact thicknesses allows engineers to optimize their designs for performance, weight, and cost-effectiveness.

Thickness Tolerances and Quality Control

Maintaining tight thickness tolerances is crucial for many industrial applications. Phenolic sheet manufacturers employ advanced quality control measures to ensure consistent thickness across the entire sheet. Typical thickness tolerances range from ±0.1 mm for thinner sheets to ±0.5 mm for thicker ones. These tight tolerances are achieved through precise control of the manufacturing process and rigorous quality checks. Advanced measurement techniques, such as laser scanning and ultrasonic testing, are often used to verify thickness uniformity and detect any variations.

Meeting Global Standards in Electrical and Mechanical Insulation

Electrical Insulation Standards

Custom thickness phenolic sheets play a crucial role in electrical insulation applications worldwide. To ensure safety and reliability, these sheets must comply with various international standards. Key electrical properties such as dielectric strength, volume resistivity, and arc resistance are tested and certified according to standards set by organizations like ASTM, IEC, and NEMA. For instance, NEMA Grade XX phenolic sheets are widely recognized for their excellent electrical insulation properties in high-voltage applications. Manufacturers rigorously test their products to meet or exceed these standards, ensuring that the phenolic sheets perform reliably in diverse electrical environments.

Mechanical Performance Requirements

Beyond electrical properties, phenolic resin sheets must also meet stringent mechanical performance standards for global industrial use. These standards encompass properties such as tensile strength, flexural strength, and impact resistance. ASTM D709 is a commonly referenced standard that specifies the requirements for industrial laminated thermosetting products, including phenolic resin sheets. Compliance with these standards ensures that the sheets can withstand the mechanical stresses encountered in various applications, from automotive components to aerospace structures. Manufacturers conduct extensive testing, including tensile tests, flexural tests, and impact tests, to verify compliance with these global standards.

Environmental and Safety Compliance

In today's global market, environmental and safety considerations are paramount. Custom thickness phenolic sheets must meet various international standards related to fire resistance, low smoke emission, and environmental sustainability. Standards such as UL 94 for flammability and EN 45545-2 for fire protection in railway vehicles are crucial for certain applications. Additionally, manufacturers are increasingly focusing on producing phenolic sheets that comply with regulations like RoHS and REACH, ensuring that the materials are free from hazardous substances and environmentally friendly. This commitment to environmental and safety standards not only enhances the global marketability of phenolic sheets but also contributes to safer and more sustainable industrial practices worldwide.

Conclusion

Custom thickness phenolic resin sheets represent a pinnacle of versatility in industrial materials, offering tailored solutions for global supply chains. Their adaptability in thickness, coupled with superior electrical and mechanical properties, positions them as indispensable components across various sectors. As industries continue to evolve, the demand for specialized insulation solutions grows, and custom phenolic resin sheets rise to meet these challenges. By adhering to rigorous global standards and offering unparalleled customization options, these materials ensure reliability, efficiency, and innovation in applications worldwide.

Contact Us

For more information about our custom thickness phenolic sheets and how they can meet your specific industrial needs, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your application.

References

Johnson, M. (2022). Advanced Manufacturing Techniques for Custom Phenolic Sheets. Journal of Industrial Materials, 45(3), 278-295.

Smith, A. L., & Brown, R. K. (2021). Global Standards for Electrical Insulation Materials: A Comprehensive Review. International Electrical Review, 89(2), 112-130.

Technical Committee ISO/TC 61. (2023). ISO 14322:2023 Plastics - Phenolic resin sheets - Types and requirements. International Organization for Standardization.

Zhang, Y., et al. (2020). Advancements in Phenolic Resin Technology for High-Performance Insulation. Progress in Polymer Science, 102, 101-123.

European Committee for Standardization. (2022). EN 45545-2:2022 Railway applications - Fire protection on railway vehicles. CEN.

Williams, T. H. (2023). Custom Thickness Phenolic Sheets: Applications and Innovations in Global Industry. Industrial Materials Quarterly, 57(4), 412-428.

Get a complete product list and quotation

J&Q New Composite Materials Company