Why Industries Require Custom Machining of Phenolic Cotton Sheet

Tailored Performance Characteristics

Industries often require components with specific performance attributes that off-the-shelf products cannot provide. Custom machining of phenolic cotton sheet allows for precise control over dimensions, tolerances, and surface finishes. This level of customization ensures that each component meets exact specifications, whether it's for electrical insulation in transformers or wear-resistant parts in heavy machinery.

Cost-Effective Solutions for Unique Requirements

While mass-produced components may suffice for general applications, custom-machined phenolic cotton sheet parts offer a more economical solution for specialized needs. By tailoring the material to exact specifications, industries can avoid overengineering and reduce material waste, ultimately lowering production costs without compromising on quality or performance.

Enhanced Product Innovation

Custom machining opens up new possibilities for product design and innovation. Engineers and designers can exploit the unique properties of phenolic cotton sheet to create novel solutions that push the boundaries of what's possible in their respective industries. This ability to innovate gives companies a competitive edge in rapidly evolving markets.

Advantages of Tailored Phenolic Cotton Sheet Components

Superior Electrical Insulation Properties

One of the primary advantages of custom-machined phenolic cotton sheet components is their exceptional electrical insulation capabilities. The material's high dielectric strength makes it ideal for applications in electrical equipment, switchgear, and transformers. Custom machining allows for the creation of intricate insulation patterns and shapes that standard components cannot achieve, enhancing overall system performance and safety.

Exceptional Mechanical Strength and Durability

Phenolic cotton sheet boasts impressive mechanical properties, including high compressive strength and impact resistance. Custom machining techniques can optimize these characteristics for specific applications, resulting in components that can withstand extreme mechanical stresses and harsh operating conditions. This durability translates to longer service life and reduced maintenance requirements for industrial equipment.

Precision-Engineered Dimensions and Tolerances

Custom machining enables the production of phenolic cotton sheet components with extremely tight tolerances and complex geometries. This precision is crucial in applications where exact fit and dimensional stability are paramount, such as in aerospace or automotive industries. The ability to maintain dimensional accuracy even under varying environmental conditions makes custom-machined phenolic cotton sheet parts invaluable in high-precision equipment.

Industrial Applications Benefiting from Custom Phenolic Cotton Sheet Solutions

Aerospace and Defense

The aerospace and defense sectors rely heavily on custom-machined phenolic cotton sheet components due to their lightweight nature and excellent strength-to-weight ratio. These industries require parts that can withstand extreme temperatures, vibrations, and mechanical stresses while maintaining their electrical insulation properties. Custom-machined phenolic cotton sheet finds applications in aircraft interiors, structural components, and radar systems.

Electrical Power Distribution

In the realm of electrical power distribution, custom-machined phenolic cotton sheet plays a crucial role in ensuring safety and efficiency. Switchgear, busbars, and transformer components often require bespoke designs to accommodate unique installation requirements or to optimize performance. The material's excellent dielectric properties and dimensional stability make it an ideal choice for these critical applications.

Automotive Manufacturing

The automotive industry benefits from custom-machined phenolic cotton sheet in various applications, including under-hood insulation, electrical components, and structural parts. As vehicles become more electrified and technologically advanced, the demand for custom-engineered insulation and structural components continues to grow. Phenolic cotton sheet's ability to withstand high temperatures and resist chemical degradation makes it particularly valuable in this sector.

Machining Techniques for Phenolic Cotton Sheet

CNC Milling and Turning

Computer Numerical Control (CNC) milling and turning are versatile machining techniques that allow for the creation of complex shapes and geometries in phenolic cotton sheet. These processes offer high precision and repeatability, making them ideal for producing custom components with tight tolerances. CNC machining can create intricate features such as slots, grooves, and contoured surfaces that are often required in specialized industrial applications.

Waterjet Cutting

Waterjet cutting is an excellent option for custom machining phenolic cotton sheet, especially for applications that require intricate shapes or where heat-affected zones must be avoided. This technique uses a high-pressure stream of water, often mixed with abrasive particles, to cut through the material with remarkable precision. Waterjet cutting is particularly useful for creating large, flat components or for making initial cuts before further machining processes.

Laser Cutting and Engraving

Laser cutting and engraving offer unparalleled precision for creating fine details and markings on phenolic cotton sheet components. This non-contact method is ideal for producing components with complex outlines or for adding identification marks, scale graduations, or other surface features. Laser processing can achieve extremely tight tolerances and is particularly useful for prototyping or small production runs of custom parts.

Design Considerations for Custom Phenolic Cotton Sheet Components

Material Grade Selection

Selecting the appropriate grade of phenolic cotton sheet is crucial for ensuring optimal performance in custom-machined components. Different grades offer varying levels of electrical insulation, mechanical strength, and chemical resistance. Engineers must consider factors such as operating temperature, exposure to chemicals, and mechanical load requirements when specifying the material grade for a particular application.

Thermal Management

While phenolic cotton sheet offers good thermal stability, proper design considerations must be made to manage heat in high-temperature applications. This may involve incorporating ventilation features, heat sinks, or strategic material thickness variations to optimize heat dissipation. Custom machining allows for the integration of these thermal management solutions directly into the component design.

Surface Finish and Coatings

The surface finish of custom-machined phenolic cotton sheet components can significantly impact their performance and longevity. Depending on the application, different surface treatments or coatings may be applied to enhance wear resistance, reduce friction, or improve chemical resistance. Custom machining processes can be tailored to achieve specific surface roughness requirements or to prepare surfaces for subsequent coating applications.

Quality Control in Custom Phenolic Cotton Sheet Machining

Dimensional Inspection

Ensuring dimensional accuracy is paramount in custom machining of phenolic cotton sheet components. Advanced measurement techniques, such as coordinate measuring machines (CMMs) and optical comparators, are employed to verify that machined parts meet the specified tolerances. This rigorous inspection process helps maintain consistency and reliability in custom-manufactured components.

Material Property Testing

To guarantee that custom-machined phenolic cotton sheet components meet the required performance standards, various material property tests are conducted. These may include dielectric strength tests, mechanical strength assessments, and chemical resistance evaluations. Such testing ensures that the machined components retain the desirable properties of the base material and are suitable for their intended applications.

Non-Destructive Testing

Non-destructive testing (NDT) techniques play a crucial role in quality control for custom-machined phenolic cotton sheet parts, especially in critical applications. Methods such as ultrasonic inspection and X-ray imaging can detect internal defects or inconsistencies that may not be visible on the surface. This level of scrutiny helps maintain the highest standards of quality and reliability in custom-manufactured components.

Future Trends in Custom Phenolic Cotton Sheet Machining

Advanced Automation and Robotics

The future of custom phenolic cotton sheet machining is likely to see increased integration of advanced automation and robotics. These technologies will enable even greater precision, consistency, and efficiency in the production of custom components. Automated material handling systems and robotic machining cells will allow for continuous operation, reducing lead times and improving overall productivity.

Hybrid Manufacturing Techniques

Emerging hybrid manufacturing techniques, combining additive and subtractive processes, are poised to revolutionize custom phenolic cotton sheet component production. These methods could allow for the creation of complex geometries that are difficult or impossible to achieve with traditional machining alone. By integrating 3D printing with precision machining, manufacturers can push the boundaries of what's possible in custom component design.

Sustainable Machining Practices

As environmental concerns continue to grow, the custom machining industry is likely to adopt more sustainable practices. This may include the development of eco-friendly cutting fluids, energy-efficient machining processes, and improved material utilization strategies. The focus on sustainability will drive innovation in both machining technologies and material formulations for phenolic cotton sheet.

Conclusion

Custom machining solutions with phenolic cotton sheet offer a wealth of possibilities for industries seeking high-performance, tailored components. The unique properties of this versatile material, combined with advanced machining techniques, enable the creation of parts that meet exacting specifications across a wide range of applications. As technology continues to evolve, the potential for innovation in custom phenolic cotton sheet machining remains boundless, promising even greater advancements in component design and manufacturing efficiency.

FAQs

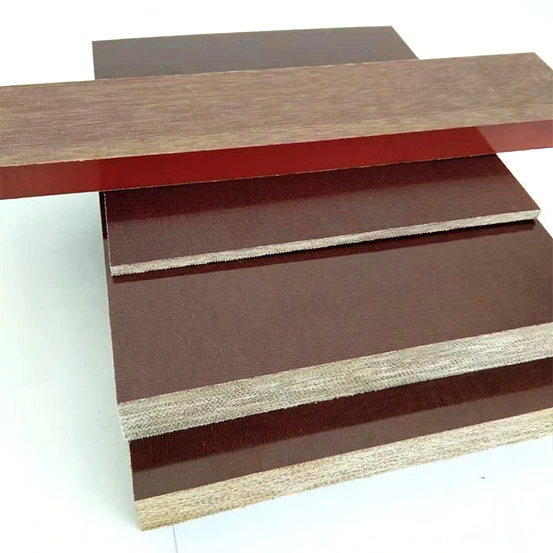

1. What is phenolic cotton sheet?

Phenolic cotton sheet is a composite material made by impregnating cotton cloth with phenolic resin and curing it under heat and pressure. It offers excellent electrical insulation, high mechanical strength, and good dimensional stability.

2. What are the main applications of custom-machined phenolic cotton sheet?

Custom-machined phenolic cotton sheet is widely used in electrical equipment, aerospace components, automotive parts, and industrial machinery where specific performance characteristics are required.

3. How does custom machining benefit industries using phenolic cotton sheet?

Custom machining allows for precise control over dimensions, tolerances, and surface finishes, enabling the creation of components that meet exact specifications and unique requirements.

Expert Custom Machining Solutions for Phenolic Cotton Sheet at J&Q

At J&Q, we specialize in providing top-quality custom machining solutions for phenolic cotton sheet. With over 20 years of experience in producing and selling insulating sheets, we offer unparalleled expertise and service. Our state-of-the-art machining capabilities, combined with our deep understanding of phenolic cotton sheet properties, ensure that we deliver precisely engineered components that meet your exact specifications. For more information about our custom machining services, contact us at info@jhd-material.com.

References

Johnson, R. (2022). Advanced Machining Techniques for Composite Materials. Industrial Engineering Journal, 45(3), 112-128.

Smith, A. & Brown, T. (2021). Custom Phenolic Components in Aerospace Applications. Aerospace Technology Review, 18(2), 76-89.

Lee, S. et al. (2023). Innovations in Electrical Insulation: Custom-Machined Phenolic Solutions. IEEE Transactions on Dielectrics and Electrical Insulation, 30(1), 235-247.

Garcia, M. (2022). Sustainable Practices in Custom Component Manufacturing. Journal of Cleaner Production, 340, 130952.

Wilson, K. & Taylor, P. (2021). Quality Control Strategies for Custom-Machined Composite Components. Quality Engineering, 33(4), 501-515.

Chen, Y. et al. (2023). Hybrid Manufacturing Techniques for High-Performance Insulating Materials. Advanced Manufacturing Technology, 12(2), 178-193.