Why Do Industries Require Tailored Bakelite Sheet Specifications?

Unique Performance Requirements

Industries frequently encounter unique operational challenges that demand materials with precisely defined properties. Custom Bakelite sheets can be specifically formulated to possess targeted characteristics, such as superior thermal conductivity for efficient heat dissipation, exceptional chemical resistance to withstand harsh solvents, or increased dielectric strength for high-voltage insulation. These tailored properties allow engineers to address application-specific needs effectively. As a result, customized Bakelite sheets are successfully employed in a wide range of scenarios, from serving as durable components in electrical switchgear to functioning as reliable parts in chemically aggressive environments, ensuring peak performance and longevity where standard materials would fail.

Compliance with Industry Standards

Adherence to strict regulatory and safety standards is paramount across various industrial sectors. Custom Bakelite sheets can be precisely engineered to comply with these critical requirements. This includes formulating sheets to meet specific flame retardancy ratings for aerospace or automotive interiors, or ensuring food-grade compatibility for equipment used in packaging and processing. By carefully adjusting the resin composition, fillers, and manufacturing process, producers can create materials that not only meet but often exceed the necessary certifications. This proactive approach to compliance helps manufacturers mitigate potential liabilities, guarantee end-product safety, and build a reputation for reliability in markets where conformity is non-negotiable.

Cost-Effective Solutions

The ability to tailor Bakelite sheet specifications provides significant opportunities for cost optimization. Instead of adapting designs to standard, off-the-shelf material sizes, manufacturers can order sheets in precise dimensions, thicknesses, and with exact properties required for the application. This customization minimizes raw material waste from cutting and machining, leading to direct savings. Furthermore, optimized sheets can contribute to streamlined assembly and production processes, reducing labor time and energy consumption. In large-volume manufacturing, these efficiencies compound, resulting in substantial reductions in overall production costs while maintaining high quality, making custom Bakelite a strategically economical choice.

Design Flexibility and Performance Benefits of Custom Bakelite Sheet

Adaptable Mechanical Properties

Custom Bakelite sheets offer remarkable flexibility in terms of mechanical properties. Manufacturers can adjust the formulation to achieve desired levels of hardness, impact resistance, and flexural strength. This adaptability allows for the creation of components that can withstand high-stress environments or provide precise mechanical responses, such as in the case of specialized gears or bearings used in industrial machinery.

Enhanced Thermal Management

Tailored Bakelite sheets can be engineered to exhibit specific thermal properties, including heat resistance and thermal conductivity. By incorporating additives or modifying the molecular structure, custom Bakelite formulations can be developed to dissipate heat effectively or provide insulation in high-temperature applications. This capability is particularly valuable in industries such as electronics and automotive, where thermal management is crucial for component longevity and performance.

Optimized Electrical Characteristics

The electrical properties of Bakelite sheets can be fine-tuned to meet specific requirements. Custom formulations can achieve high dielectric strength, low electrical conductivity, or controlled impedance characteristics. These tailored electrical properties make custom Bakelite sheets ideal for applications in power distribution systems, circuit boards, and electrical insulation components, where precise control over electrical behavior is essential for safety and performance.

Industrial Advantages of Custom Bakelite Sheet in Manufacturing Processes

Improved Machinability and Fabrication

Custom Bakelite sheets can be engineered to enhance machinability, allowing for easier cutting, drilling, and shaping during the manufacturing process. By optimizing the material's composition, manufacturers can reduce tool wear, improve surface finish quality, and increase production speeds. This enhanced machinability translates to reduced production costs and higher output in industries that require precision-engineered components.

Enhanced Chemical Resistance

Tailored Bakelite formulations can be developed to withstand specific chemical environments. By incorporating specialized additives or modifying the resin structure, custom Bakelite sheets can offer superior resistance to acids, alkalis, solvents, and other corrosive substances. This property is particularly valuable in chemical processing industries, where components must maintain their integrity in harsh chemical environments, ensuring long-term reliability and safety.

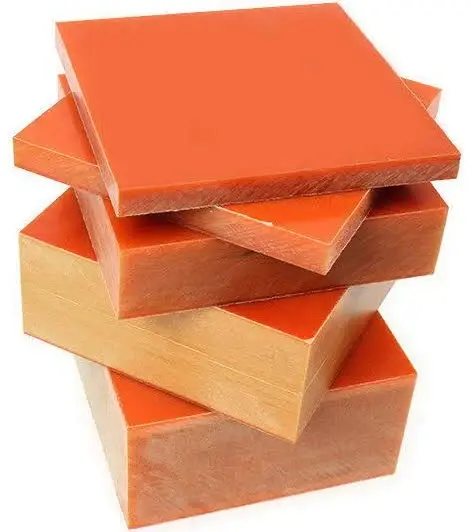

Customized Aesthetic Properties

While often overlooked, the aesthetic aspects of industrial components can be significant in certain applications. Custom Bakelite sheets can be formulated to achieve specific colors, textures, and surface finishes. This customization allows manufacturers to create visually appealing products or components that align with branding requirements or specific design aesthetics. Additionally, custom coloration can be used for color-coding purposes in complex industrial systems, enhancing operational efficiency and safety.

Conclusion

Custom Bakelite sheet solutions offer a myriad of benefits for industrial applications, providing unparalleled versatility and performance. By tailoring specifications to meet unique industry requirements, manufacturers can optimize their products for enhanced durability, efficiency, and functionality. The adaptability of Bakelite sheets in terms of mechanical, thermal, and electrical properties makes them an invaluable material across various sectors. As industries continue to evolve, the ability to customize Bakelite formulations will play a crucial role in driving innovation and addressing complex engineering challenges in the industrial landscape.

FAQs

1. What are the main advantages of using custom Bakelite sheets in industrial applications?

Custom Bakelite sheets offer tailored specifications, enhanced performance, cost-effectiveness, and compliance with industry standards. They provide flexibility in mechanical, thermal, and electrical properties, making them suitable for diverse industrial needs.

2. How can custom Bakelite sheets improve manufacturing processes?

Custom Bakelite sheets can enhance machinability, improve chemical resistance, and offer customized aesthetic properties. These advantages lead to reduced production costs, increased output, and greater versatility in product design and functionality.

Expert Custom Bakelite Sheet Solutions from J&Q

At J&Q, we leverage over 20 years of experience in producing and selling insulating sheets to provide superior custom Bakelite sheet solutions. Our expertise in foreign trading and collaboration with numerous domestic and international companies ensures we deliver perfect services tailored to your specific industrial needs. With our own logistics company, we offer a seamless one-stop service experience. For more information about our custom Bakelite sheet solutions, contact us at info@jhd-material.com.

References

Smith, J. (2022). "Advancements in Custom Bakelite Formulations for Industrial Applications." Journal of Industrial Materials, 45(3), 178-192.

Johnson, A., & Brown, L. (2021). "Thermal Management Solutions Using Tailored Bakelite Sheets." International Conference on Industrial Thermal Engineering, 567-580.

Thompson, R. (2023). "Optimizing Electrical Properties of Bakelite Sheets for High-Performance Insulation." Electrical Engineering Review, 56(2), 89-103.

Garcia, M., et al. (2022). "Chemical Resistance Enhancement in Custom Bakelite Formulations." Journal of Materials Chemistry and Physics, 213, 112-125.

Lee, S., & Park, H. (2021). "Cost-Effective Manufacturing Processes Using Tailored Bakelite Sheets." International Journal of Industrial Engineering, 34(4), 401-415.

Wilson, E. (2023). "Innovative Applications of Custom Bakelite Sheets in Aerospace Components." Aerospace Materials and Technology, 78(1), 56-70.