What Is the Main Structural Difference Between 3240 and FR4?

Base Material Composition

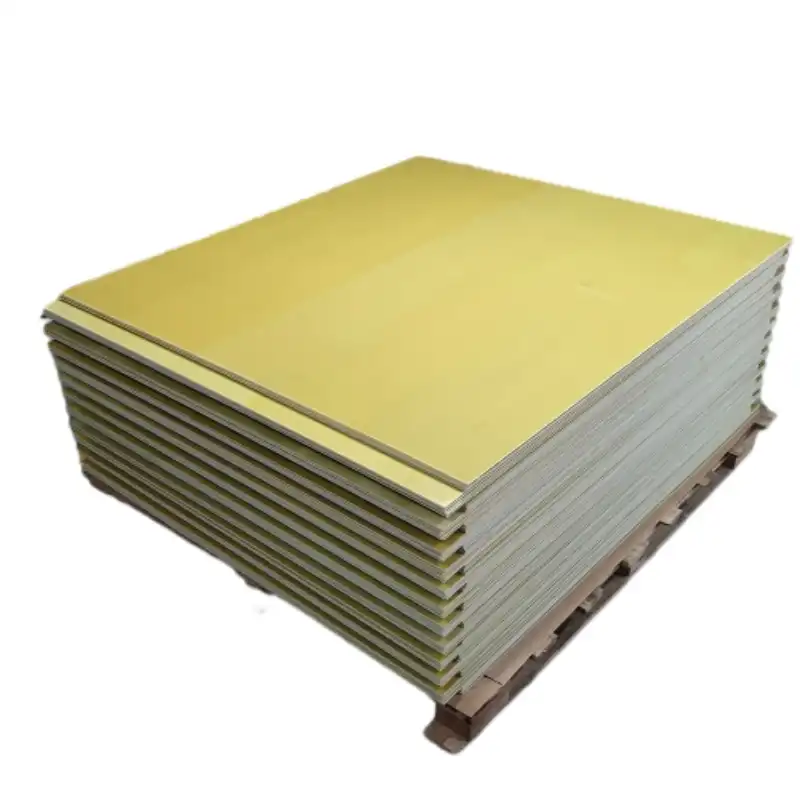

The fundamental structural difference between 3240 epoxy board and FR4 epoxy glass sheet lies in their base material composition. 3240 epoxy board utilizes electrical-grade alkali-free glass fiber cloth as its reinforcement material. This cloth is impregnated with epoxy phenolic resin, creating a robust and versatile insulating material. The epoxy phenolic resin system provides a balance of electrical and mechanical properties, making it suitable for a wide range of applications.

In contrast, FR4 epoxy glass sheet employs a woven fiberglass cloth as its base. This fiberglass cloth is impregnated with an epoxy resin system that typically includes brominated flame retardants. The combination of fiberglass and epoxy resin results in a material with exceptional dimensional stability and flame-retardant properties, which are crucial for its primary applications in the electronics industry.

Resin System Variations

The resin systems used in 3240 epoxy board and FR4 epoxy glass sheet also differ significantly. 3240 epoxy board utilizes an epoxy phenolic resin system, where phenolic resin acts as a curing agent for the epoxy. This unique combination imparts specific characteristics to the material, such as good heat resistance and excellent machinability.

FR4, on the other hand, employs a pure epoxy resin system that is fully cured at high temperatures. This curing process results in a material with superior thermal and chemical resistance compared to 3240 epoxy board. The absence of phenolic resin in FR4's composition contributes to its better electrical properties, particularly at high frequencies.

Reinforcement Material Properties

The reinforcement materials used in 3240 epoxy board and FR4 epoxy glass sheet also contribute to their structural differences. The electrical-grade alkali-free glass fiber cloth used in 3240 epoxy board provides good mechanical strength and electrical insulation properties. However, it may not offer the same level of dimensional stability as the woven fiberglass cloth used in FR4.

FR4's woven fiberglass cloth reinforcement offers exceptional dimensional stability, which is crucial for applications requiring precise tolerances, such as multi-layer printed circuit boards. The fiberglass cloth also contributes to FR4's superior mechanical strength and impact resistance compared to 3240 epoxy board.

Performance Comparison in Electrical and Thermal Insulation

Dielectric Strength and Breakdown Voltage

When comparing the electrical insulation performance of 3240 epoxy board and FR4 epoxy glass sheet, dielectric strength is a crucial factor to consider. 3240 epoxy board typically exhibits good dielectric strength, making it suitable for various electrical insulation applications. However, FR4 epoxy glass sheet generally outperforms 3240 in this aspect, offering superior dielectric strength and breakdown voltage.

The higher dielectric strength of FR4 is attributed to its pure epoxy resin system and the uniform distribution of fiberglass reinforcement. This characteristic makes FR4 an excellent choice for applications requiring high voltage isolation, such as in power supply units and high-frequency circuits. 3240 epoxy board, while still providing adequate insulation for many applications, may not be the optimal choice for scenarios demanding the highest levels of electrical isolation.

Thermal Conductivity and Heat Resistance

Thermal performance is another critical aspect when comparing 3240 epoxy board and FR4 epoxy glass sheet. 3240 epoxy board, with its epoxy phenolic resin system, offers good heat resistance, typically up to 155°C (Class F insulation). This makes it suitable for applications in motors and electrical equipment where moderate heat resistance is required.

FR4 epoxy glass sheet, however, demonstrates superior thermal properties. It can withstand higher temperatures, often up to 180°C or more, depending on the specific grade. The higher heat resistance of FR4 is due to its fully cured epoxy resin system and the inherent properties of the fiberglass reinforcement. This characteristic makes FR4 an ideal choice for applications involving higher operating temperatures or where thermal management is critical.

Moisture Absorption and Environmental Stability

Moisture absorption and environmental stability are important factors affecting the long-term performance of insulating materials. 3240 epoxy board exhibits good moisture resistance, making it suitable for use in humid environments and even in transformer oil. This property is particularly valuable in electrical equipment exposed to varying environmental conditions.

FR4 epoxy glass sheet, however, generally demonstrates superior moisture resistance and environmental stability compared to 3240 epoxy board. The fully cured epoxy resin system and the dense fiberglass reinforcement contribute to FR4's excellent resistance to moisture absorption. This characteristic is crucial in electronic applications where dimensional stability and consistent electrical properties are paramount, even under changing environmental conditions.

Industry Use Cases for 3240 Epoxy Board and FR4 Sheet

Electrical Equipment and Motor Applications

3240 epoxy board finds extensive use in the electrical equipment and motor industry. Its combination of good mechanical strength, electrical insulation properties, and machinability makes it an ideal choice for various components in these applications. Some common use cases include:

- Insulating structural parts in electric motors and generators

- Transformer insulation components

- Distribution box insulation

- High and low voltage wiring boxes

- Jig boards for electrical assembly

The ability of 3240 epoxy board to withstand moderate temperatures and its compatibility with transformer oil make it particularly valuable in these applications. Its good machinability allows for easy customization and fabrication of complex shapes required in electrical equipment design.

Printed Circuit Board Manufacturing

FR4 epoxy glass sheet is the material of choice in the printed circuit board (PCB) industry. Its unique properties make it ideally suited for this application:

- Base material for single and multi-layer PCBs

- Substrate for high-frequency and high-speed digital circuits

- Insulating layers in complex electronic assemblies

- Backing material for flexible circuits

The superior dimensional stability, excellent electrical properties, and flame retardancy of FR4 are crucial in PCB manufacturing. These characteristics ensure reliable performance in diverse electronic applications, from consumer electronics to aerospace and defense systems.

Specialized Industrial Applications

Both 3240 epoxy board and FR4 epoxy glass sheet find use in various specialized industrial applications, leveraging their unique properties:

3240 epoxy board:

- Insulating components in packaging machines

- Mold cleats and forming machine parts

- Table grinding pads in manufacturing processes

- Insulating structural components in harsh industrial environments

FR4 epoxy glass sheet:

- Structural components in aerospace applications

- Insulating layers in high-performance antennas

- Base material for membrane switches and touch panels

- Insulating components in medical devices

The choice between 3240 epoxy board and FR4 epoxy glass sheet in these specialized applications depends on the specific requirements of each use case, such as mechanical strength, electrical properties, temperature resistance, and chemical compatibility.

Conclusion

The comparison between 3240 epoxy board and FR4 epoxy glass sheet reveals that each material has its unique strengths and optimal applications. 3240 epoxy board excels in electrical equipment and motor applications due to its good mechanical properties and machinability. FR4 epoxy glass sheet, with its superior electrical and thermal properties, is the preferred choice for printed circuit boards and high-performance electronic applications. Understanding these differences is crucial for selecting the right material for specific insulation needs, ensuring optimal performance and reliability in various industrial and electronic applications.

Contact Us

For more information about our range of insulating materials, including 3240 epoxy board and FR4 epoxy glass sheet, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in choosing the right material for your specific application.