What Makes G10 Ideal for CNC Machining?

Superior Mechanical Properties

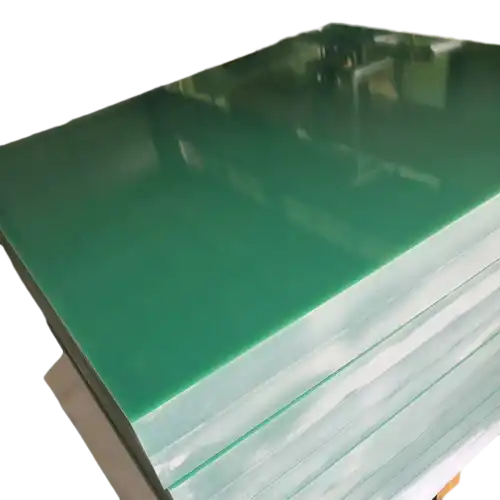

G10 sheets are renowned for their exceptional mechanical strength, rigidity, and impact resistance, which arise from their composition of woven glass fibers thoroughly impregnated with epoxy resin. This unique combination results in a material that boasts a high strength-to-weight ratio, making it an ideal choice for applications where minimizing weight is essential without sacrificing structural integrity. The durability of G10 ensures long-lasting performance in demanding environments, while its toughness allows it to withstand heavy mechanical stress, making it suitable for use in aerospace, automotive, and industrial sectors where reliability is critical.

Excellent Machinability

Despite its toughness, G10 exhibits excellent machinability, making it highly compatible with CNC machining processes. The homogeneous structure of the material allows CNC tools to cut, mill, and drill G10 sheets cleanly and precisely, producing complex shapes and intricate components with high accuracy and repeatability. Additionally, G10 does not cause excessive tool wear or produce harmful dust during machining, ensuring a safer working environment and reducing operational costs. This consistent machinability leads to faster production cycles, optimized CNC programming, and minimized setup times, significantly improving manufacturing efficiency.

Thermal Stability

G10 sheets demonstrate outstanding dimensional stability across a broad temperature range, a critical factor in CNC machining applications where heat generation during cutting can cause deformation in lesser materials. This thermal stability ensures that G10 maintains its shape and size even when exposed to fluctuating or elevated temperatures, preventing warping or expansion that could compromise part accuracy. Consequently, machined components retain precise dimensions throughout production, leading to superior product quality and significantly lower scrap rates. This makes G10 particularly valuable in OEM manufacturing environments where tight tolerances and consistency are paramount.

Dimensional Stability and Precision Cutting Performance

Low Moisture Absorption

G10 sheets exhibit remarkably low moisture absorption rates, contributing significantly to their dimensional stability. This property is crucial for maintaining tight tolerances in machined parts, especially in environments with varying humidity levels. The material's resistance to moisture-induced swelling or shrinkage ensures that CNC-cut components retain their exact dimensions over time, enhancing product reliability and longevity.

Uniform Internal Structure

The consistent internal structure of G10 sheets plays a vital role in achieving precision cutting performance. Unlike some composite materials that may have voids or inconsistencies, G10's uniform composition allows for predictable material behavior during CNC operations. This homogeneity facilitates the creation of complex geometries with smooth surface finishes, reducing the need for post-machining processes and improving overall part quality.

High-Resolution Edge Definition

CNC machining of G10 sheets results in exceptionally clean and well-defined edges. The material's unique composition prevents fraying or delamination during cutting operations, allowing for the production of parts with sharp corners and intricate details. This high-resolution edge definition is particularly valuable in applications requiring tight-fitting components or precise interlocking mechanisms, common in many OEM products.

OEM Applications in Aerospace, Automotive, and Electronics

Aerospace Component Manufacturing

In the aerospace industry, CNC-Ready G10 sheets find extensive use in manufacturing structural components, insulation panels, and electrical systems. The material's high strength-to-weight ratio makes it ideal for creating lightweight yet durable parts that contribute to fuel efficiency and aircraft performance. G10's excellent electrical insulation properties also make it suitable for producing circuit boards and avionics housings that can withstand the extreme conditions encountered during flight.

Automotive Parts Production

Automotive OEMs leverage G10 sheets for producing a wide range of components, from underhood insulators to interior trim pieces. The material's ability to withstand high temperatures and resist chemical degradation makes it suitable for engine compartment applications. CNC machining of G10 allows for the creation of complex shapes and integrated features, reducing the need for assembly and improving overall vehicle design. Additionally, G10's electrical insulation properties make it valuable in the production of components for electric and hybrid vehicles.

Electronics Manufacturing

The electronics industry relies heavily on CNC-machined G10 sheets for producing printed circuit boards (PCBs), insulators, and protective enclosures. The material's excellent dielectric properties and dimensional stability ensure consistent performance in electronic devices. CNC machining enables the creation of precise cutouts, mounting holes, and channels in G10 sheets, facilitating the integration of electronic components and optimizing device layouts. The material's flame-retardant properties also contribute to improved safety in consumer electronics and industrial control systems.

Conclusion

CNC-Ready G10 sheets have emerged as a game-changer in OEM production across aerospace, automotive, and electronics industries. Their exceptional machinability, dimensional stability, and versatile properties make them ideal for creating high-precision components with complex geometries. By leveraging G10 sheets in CNC machining processes, manufacturers can achieve tighter tolerances, improved product quality, and enhanced production efficiency. As OEMs continue to push the boundaries of innovation, CNC-Ready G10 sheets will undoubtedly play a crucial role in shaping the future of advanced manufacturing.

Contact Us

To learn more about how CNC-Ready G10 sheets can revolutionize your OEM production, contact us at info@jhd-material.com. Our team of experts is ready to help you unlock the full potential of this remarkable material for your specific applications.