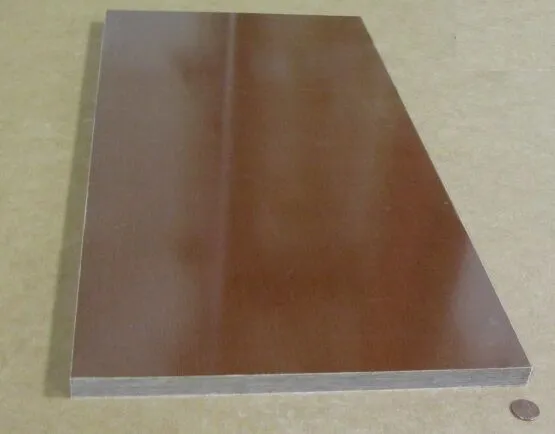

What Types of Coatings Are Compatible with Phenolic Surfaces?

Epoxy-Based Coatings

Epoxy-based coatings exhibit excellent compatibility with phenolic cotton cloth sheets, making them a preferred choice in demanding industrial environments. These coatings provide strong adhesion to the phenolic surface, resulting in a durable and resilient finish. Their chemical resistance protects the underlying material from exposure to oils, solvents, acids, and other harsh chemicals, thereby extending the service life of phenolic sheets. Additionally, epoxy coatings cure to form a hard, impact-resistant surface that maintains integrity even under mechanical stress, ensuring long-term protection and minimal maintenance requirements in industrial applications.

Polyurethane Paints

Polyurethane paints offer a flexible and durable coating solution for phenolic surfaces, adapting well to the material’s slight dimensional changes caused by thermal expansion or contraction. These coatings form a tough, elastic film that resists abrasion and mechanical wear, which is essential for applications subjected to frequent handling or harsh conditions. Furthermore, polyurethane paints provide superior resistance to ultraviolet (UV) radiation, preventing degradation and discoloration when exposed to sunlight. This combination of flexibility, abrasion resistance, and UV stability makes polyurethane coatings ideal for both indoor and outdoor phenolic sheet applications.

Specialized Phenolic Primers

Applying specialized phenolic primers before painting is critical to achieving strong adhesion on phenolic cotton cloth sheets. These primers are formulated specifically to bond effectively with the smooth, often non-porous phenolic surfaces, creating a receptive base layer for subsequent paint layers. By improving paint adhesion, phenolic primers expand the variety of coatings that can be successfully applied, ensuring better coverage and longevity. In addition to adhesion enhancement, some primers incorporate additives that boost moisture resistance or enhance electrical insulation, further improving the functional performance of coated phenolic sheets in diverse industrial settings.

Surface Preparation and Adhesion Considerations

Cleaning and Degreasing

Proper surface preparation is crucial for successful paint adhesion on phenolic cotton cloth sheets. The first step involves thorough cleaning and degreasing of the surface. Any oils, dirt, or contaminants can interfere with paint adhesion. Use a solvent-based degreaser or a specialized cleaner designed for phenolic materials. After cleaning, ensure the surface is completely dry before proceeding to the next step.

Surface Roughening

The smooth surface of phenolic cotton cloth sheets can be a challenge for paint adhesion. Lightly sanding the surface with fine-grit sandpaper can create a slightly roughened texture that provides better grip for the paint. This process, known as scuffing, increases the surface area and creates micro-abrasions that allow the paint to form a stronger bond. Be careful not to sand too aggressively, as this could compromise the sheet's structural integrity or electrical properties.

Adhesion Promoters

In addition to primers, adhesion promoters can be used to enhance paint bonding on phenolic surfaces. These specialized products are designed to create a chemical bridge between the phenolic material and the paint. They're particularly useful when working with challenging surfaces or when maximum adhesion is required. Adhesion promoters can be applied as a separate step or may be incorporated into some primer formulations.

Industrial Applications Requiring Painted Phenolic Panels

Electrical Enclosures

Phenolic cotton cloth sheets are widely used in electrical enclosures due to their excellent insulation properties. Painting these enclosures serves multiple purposes. It can enhance the aesthetics of the equipment, making it more visually appealing in industrial settings. More importantly, certain paints can provide additional protection against moisture and environmental factors, potentially extending the lifespan of the enclosure. Color coding through paint can also be used to indicate voltage levels or specific functions, improving safety and ease of identification in complex electrical systems.

Marine Applications

In marine environments, phenolic materials are valued for their resistance to moisture and chemicals. Painting phenolic panels used in boat construction or marine equipment serves to further enhance these properties. Specialized marine-grade paints can provide additional protection against saltwater, UV radiation, and extreme weather conditions. These coatings not only preserve the phenolic material but can also contribute to the overall aesthetics of the vessel or equipment.

Aerospace Components

The aerospace industry utilizes phenolic cotton cloth sheets in various applications due to their lightweight nature and heat resistance. Painting these components can serve functional and aesthetic purposes. Specialized aerospace coatings can provide additional heat resistance, reduce radar signatures, or even add anti-static properties. In some cases, the paint may also act as a sealant, further protecting the phenolic material from environmental factors encountered at high altitudes or during rapid temperature changes.

Conclusion

Painting phenolic cotton cloth sheets is indeed possible and can be beneficial in many industrial applications. The key to success lies in proper surface preparation, selecting compatible coatings, and following appropriate application techniques. While the process requires careful consideration and specialized materials, the results can significantly enhance the functionality and appearance of phenolic components. As technology advances, new coating options continue to emerge, offering improved adhesion and additional protective properties for phenolic surfaces.

Contact Us

For more information about phenolic cotton cloth sheets and their applications, or to discuss your specific needs, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the best solutions for your industrial requirements.