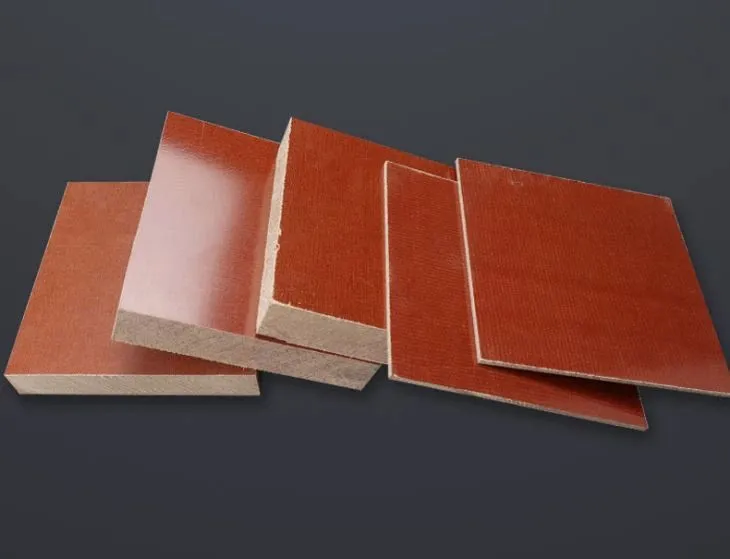

Where Are Phenolic Cotton Sheets Commonly Used?

Electrical Industry Applications

In the electrical industry, phenolic cotton cloth laminated sheets are indispensable for their superior insulation properties. These sheets are commonly used in the fabrication of transformer components, switchgear panels, and circuit breaker parts. Their low electrical conductivity and high dielectric strength make them ideal for preventing current leakage and ensuring the safe operation of electrical equipment. Moreover, their resistance to tracking and arc erosion enhances the longevity of electrical systems in high-voltage environments.

Mechanical Engineering Uses

Mechanical engineers rely on phenolic cotton cloth laminated sheets for their exceptional strength and wear resistance. These materials are frequently employed in the production of gears, bearings, and bushings, especially in applications where metal components might be prone to corrosion or excessive wear. The sheets' low friction coefficient contributes to improved efficiency in moving parts, while their ability to maintain dimensional stability under varying temperatures ensures consistent performance in diverse operating conditions.

Aerospace and Transportation Applications

The aerospace and transportation sectors leverage the lightweight yet robust nature of phenolic cotton cloth laminated sheets. These materials are utilized in aircraft interiors, automotive components, and railway equipment. Their flame-retardant properties and ability to withstand vibration make them particularly valuable in these industries where safety and reliability are paramount. From seat backs to structural supports, these sheets contribute to reducing overall vehicle weight without compromising on strength or safety standards.

Electrical and Mechanical Strength in Industrial Settings

Power Generation and Distribution

In power generation and distribution facilities, phenolic cotton cloth laminated sheets play a critical role in ensuring the reliable operation of equipment. These sheets are used to manufacture insulating components for high-voltage transformers, busbars, and switchgear. Their ability to maintain electrical insulation properties under extreme temperatures and humidity levels makes them invaluable in maintaining the integrity of power distribution networks. Additionally, their resistance to oil and chemicals commonly found in industrial environments enhances their durability and reliability in these critical applications.

Industrial Machinery and Equipment

Industrial machinery benefits greatly from the use of phenolic cotton cloth laminated sheets. These materials are employed in the construction of machine guards, conveyor components, and industrial rollers. Their high impact resistance and ability to withstand continuous mechanical stress make them ideal for applications in harsh manufacturing environments. The sheets' low moisture absorption rate also contributes to their longevity in humid or wet conditions, reducing maintenance requirements and improving overall equipment reliability.

Mining and Oil & Gas Industries

The mining and oil & gas sectors rely on phenolic cotton cloth laminated sheets for their exceptional resistance to chemicals and abrasion. These materials are used in the fabrication of pump components, valve seats, and sealing elements in drilling equipment. Their ability to maintain structural integrity in the presence of corrosive fluids and under high pressures makes them essential in these demanding industries. Furthermore, their electrical insulation properties contribute to the safety of equipment operating in potentially explosive atmospheres.

Advantages in Automotive and Transformer Insulation

Automotive Sector Benefits

The automotive industry capitalizes on the unique properties of phenolic cotton cloth laminated sheets to enhance vehicle performance and safety. These materials are used in the production of underhood components, such as gaskets and heat shields, where their heat resistance and dimensional stability are crucial. Their application in brake systems, particularly in the manufacturing of brake pads and clutch facings, takes advantage of their excellent friction and wear characteristics. The sheets' ability to dampen vibration also makes them valuable in reducing noise and improving ride comfort in vehicles.

Transformer Insulation Advantages

In the realm of transformer insulation, phenolic cotton cloth laminated sheets offer unparalleled benefits. Their high dielectric strength and low dielectric losses make them ideal for insulating transformer windings and cores. These materials maintain their insulating properties even when subjected to high temperatures and oil immersion, which are common conditions in transformer operation. The sheets' resistance to electrical tracking and partial discharge further enhances the reliability and lifespan of transformers, contributing to the overall efficiency of power distribution systems.

Thermal Management Applications

Phenolic cotton cloth laminated sheets excel in thermal management applications across various industries. Their low thermal conductivity makes them effective insulators in scenarios where heat retention or dissipation is critical. In industrial ovens and furnaces, these materials are used to create thermal barriers, improving energy efficiency. Their application in the construction of heat shields for automotive and aerospace components helps protect sensitive equipment from extreme temperatures. The sheets' ability to maintain their properties across a wide temperature range makes them invaluable in designing thermal management solutions for complex industrial processes.

Conclusion

Phenolic cotton cloth laminated sheets have proven to be indispensable in a wide array of applications across multiple industries. Their unique combination of electrical insulation, mechanical strength, and thermal resistance properties makes them a versatile material choice for engineers and designers. From ensuring the safety and efficiency of electrical systems to enhancing the performance of automotive components, these sheets continue to play a crucial role in advancing technology and improving industrial processes. As industries evolve and face new challenges, the adaptability and reliability of phenolic cotton cloth laminated sheets ensure their continued relevance in solving complex engineering problems.

Contact Us

For more information about our high-quality phenolic cotton cloth laminated sheets and how they can benefit your specific application, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your needs.