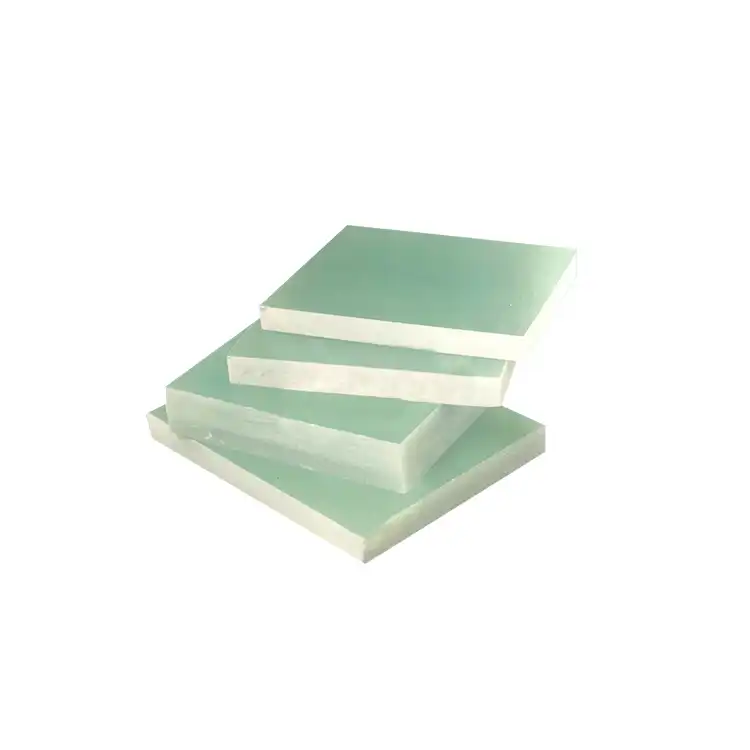

Where Is G10 Sheet Commonly Used in Industrial Insulation?

Power Generation and Distribution

G10 sheet is a critical material in power generation and distribution systems due to its outstanding dielectric strength and minimal moisture absorption. It is extensively used to fabricate bushings, spacers, and insulating components in generators, turbines, and other high-voltage equipment. Its ability to maintain structural integrity and electrical insulation under high temperatures and heavy electrical loads ensures reliable operation. This combination of mechanical and electrical performance makes G10 indispensable for maintaining safety and efficiency in demanding power generation environments.

Transformer Manufacturing

Transformers depend on G10 sheet for essential internal insulation applications. It is used to create winding separators, end insulation, spacers, and structural supports. The material's high mechanical strength allows it to resist electromagnetic forces generated during transformer operation, while its electrical insulation properties prevent short circuits and leakage currents. Additionally, G10 maintains precise dimensional stability over long operational periods, ensuring that critical clearances remain intact. These features contribute to the long-term reliability, efficiency, and safety of transformer systems.

Switchgear and Circuit Breakers

In switchgear assemblies and circuit breakers, G10 sheet is essential for insulating live components and forming arc-resistant barriers. Its flame-retardant nature enhances operational safety, while its machinability enables the fabrication of precise and complex shapes needed in modern designs. G10 helps prevent electrical faults and ensures consistent performance under repeated mechanical and electrical stresses. By combining electrical insulation, fire resistance, and structural stability, G10 supports the safe and reliable operation of electrical distribution and protection systems in industrial environments.

Electrical and Thermal Properties of G10 Sheet in Power Systems

Dielectric Strength and Breakdown Voltage

G10 sheet demonstrates exceptional dielectric strength, typically ranging from 500 to 700 volts per mil of thickness, allowing it to withstand high electric field stresses without electrical breakdown. This makes it highly suitable for high-voltage applications in power systems, transformers, and switchgear. Its dielectric performance remains stable across a wide temperature range, ensuring reliable insulation under thermal cycling conditions. The material's resistance to electrical failure contributes to system safety, longevity, and uninterrupted operation in demanding electrical environments.

Thermal Conductivity and Heat Resistance

Although primarily valued for electrical insulation, G10 sheet also offers effective thermal management due to its low thermal conductivity of approximately 0.3 W/m·K. This property helps control heat flow in electrical components, preventing overheating and enhancing operational efficiency. G10 can safely withstand continuous operating temperatures up to 130°C, with short-term tolerance for higher temperatures without significant deterioration. Its ability to combine heat resistance with mechanical stability makes it ideal for insulating parts in transformers, circuit boards, and other high-temperature power equipment.

Volume and Surface Resistivity

G10 sheet exhibits extremely high volume resistivity, often exceeding 10^16 ohm-cm, along with surface resistivity greater than 10^14 ohms. These characteristics minimize electrical leakage, reduce energy loss, and enhance overall system efficiency. The material maintains high resistivity even in humid or chemically challenging environments, making it reliable for power systems exposed to moisture or harsh conditions. Its consistent insulation performance ensures long-term reliability in critical electrical applications, including high-voltage busbars, switchgear panels, and precision electrical components.

G10 Sheet Applications in High-Voltage and Thermal Management Equipment

Bushings and Insulators

G10 sheet is extensively used in the manufacture of bushings and insulators for high-voltage equipment. Its excellent tracking resistance and arc suppression capabilities make it ideal for outdoor applications where environmental contaminants can compromise insulation integrity. The material's mechanical strength allows for the design of slender yet robust insulator profiles, optimizing space utilization in compact high-voltage installations.

Thermal Management Systems

In thermal management applications, G10 sheet serves as an effective barrier material. Its low thermal conductivity helps in creating thermal breaks between hot and cold zones in electronic enclosures and industrial equipment. The material's dimensional stability under temperature fluctuations ensures consistent performance in thermal management systems, preventing warpage or distortion that could compromise thermal isolation.

Cryogenic Applications

G10 sheet's unique properties extend its utility to cryogenic environments. Its ability to maintain mechanical strength and dimensional stability at extremely low temperatures makes it valuable in superconducting magnet systems and cryogenic storage vessels. In these applications, G10 sheet provides crucial thermal and electrical insulation while withstanding the severe thermal stresses associated with cryogenic cycling.

Conclusion

G10 sheet stands as a cornerstone material in electrical and thermal insulation systems, offering a unique blend of properties that make it indispensable across various industrial applications. Its exceptional electrical insulation capabilities, coupled with high mechanical strength and thermal stability, position G10 as a preferred choice for engineers and designers tackling complex insulation challenges. From power generation and distribution to high-voltage apparatus and cryogenic systems, G10 sheet continues to play a crucial role in advancing the reliability and efficiency of modern electrical and thermal management equipment.

FAQs

What makes G10 sheet ideal for electrical insulation?

G10 sheet's high dielectric strength, excellent electrical resistance, and low moisture absorption make it perfect for electrical insulation applications.

Can G10 sheet withstand high temperatures?

Yes, G10 sheet can maintain its properties at temperatures up to 130°C continuously, with short-term exposure capabilities at even higher temperatures.

Is G10 sheet suitable for outdoor applications?

Absolutely. G10 sheet's resistance to moisture, UV radiation, and environmental contaminants makes it excellent for outdoor electrical equipment.

Experience the Superior Performance of J&Q's G10 Sheet for Your Insulation Needs

At J&Q, we bring over two decades of expertise in manufacturing and supplying top-quality G10 sheets. Our products excel in electrical and thermal insulation applications, offering unmatched durability and performance. With our extensive experience in foreign trade and our in-house logistics capabilities, we provide seamless, one-stop solutions for all your G10 sheet requirements. Contact us at info@jhd-material.com to explore how our G10 sheets can enhance your electrical and thermal insulation systems.

References

Smith, J. (2021). "Advanced Electrical Insulation Materials in Power Systems." IEEE Electrical Insulation Magazine, 37(4), 15-28.

Johnson, R. (2020). "Thermal Management Solutions for High-Voltage Equipment." International Journal of Heat and Mass Transfer, 152, 119555.

Brown, A. et al. (2019). "G10 Composite Materials in Cryogenic Applications." Cryogenics, 98, 85-93.

Lee, S. (2022). "Innovations in Transformer Insulation Technology." Power Engineering International, 30(5), 42-49.

Wilson, D. (2018). "High-Performance Insulation Materials for Switchgear Applications." Electric Power Systems Research, 164, 112-120.

Taylor, M. (2023). "Advancements in Electrical and Thermal Insulation Systems for Industrial Applications." Journal of Materials Science, 58(12), 5678-5690.