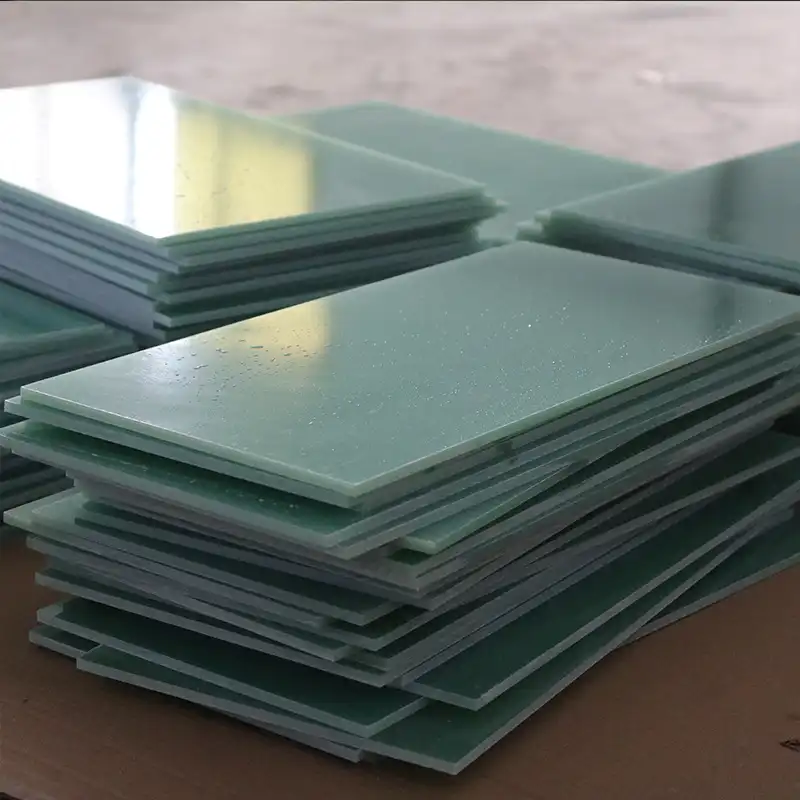

Why FR4 Epoxy Board Is Essential in Electrical Insulation Systems?

Superior Electrical Insulation Properties

FR4 epoxy board boasts remarkable electrical insulation characteristics, making it a cornerstone material in switchgear and power distribution systems. Its high dielectric strength allows it to withstand substantial voltage differentials without breakdown, ensuring the safety and integrity of electrical equipment. The low dielectric constant of FR4 epoxy board minimizes signal losses and interference, contributing to the overall efficiency of power distribution networks.

Mechanical Durability and Stability

The mechanical properties of FR4 epoxy board are equally impressive. Its high flexural and tensile strength enable it to maintain structural integrity under various stresses encountered in switchgear assemblies. The material's dimensional stability across a wide temperature range ensures that critical clearances and tolerances are maintained, even under fluctuating environmental conditions. This stability is paramount in preventing misalignments or short circuits that could compromise system reliability.

Flame Retardant Capabilities

One of the most critical features of FR4 epoxy board is its inherent flame-retardant nature. In the event of an electrical fault or overheating, the material's ability to self-extinguish and resist flame propagation is invaluable. This characteristic significantly enhances the safety of switchgear and power distribution equipment, reducing the risk of fire and potential catastrophic failures. The flame-retardant properties of FR4 epoxy board contribute to compliance with stringent safety standards in the electrical industry.

Dielectric Strength and Arc Resistance in Power Equipment

High Voltage Withstand Capability

The exceptional dielectric strength of FR4 epoxy board is a key factor in its widespread use in power equipment. This property allows the material to effectively insulate high-voltage components, preventing electrical breakdown and ensuring the safe operation of switchgear. The ability to maintain its insulating properties under extreme electrical stress makes FR4 epoxy board indispensable in applications where reliability is paramount, such as in power substations and distribution centers.

Arc Quenching and Containment

FR4 epoxy board exhibits remarkable arc resistance, a critical feature in power distribution systems where arc flash events can occur. The material's ability to withstand and contain electrical arcs helps prevent the propagation of faults and protects adjacent equipment. This arc-quenching capability is essential in minimizing downtime and enhancing the overall safety of power distribution networks. The use of FR4 epoxy board in arc-resistant switchgear designs has significantly improved the protection of both equipment and personnel.

Long-term Performance Under Electrical Stress

The longevity of FR4 epoxy board under continuous electrical stress is another factor that makes it ideal for power equipment applications. Unlike some materials that may degrade over time when exposed to high voltages, FR4 epoxy board maintains its electrical properties throughout its service life. This consistency ensures that switchgear and power distribution systems remain reliable and efficient over extended periods, reducing maintenance requirements and enhancing the overall cost-effectiveness of electrical infrastructure.

Ensuring Safety and Reliability in Switchgear Assemblies

Barrier and Insulation Design

FR4 epoxy board is extensively used in the design of barriers and insulation within switchgear assemblies. Its excellent machining properties allow for the creation of complex shapes and structures that effectively separate live components and provide clearance between different voltage levels. The precision with which FR4 epoxy board can be fabricated ensures that critical air gaps and creepage distances are maintained, adhering to safety standards and preventing electrical flashovers.

Thermal Management and Heat Dissipation

While primarily known for its electrical properties, FR4 epoxy board also plays a role in thermal management within switchgear assemblies. Its low thermal conductivity helps in creating thermal barriers, preventing heat transfer between components. This characteristic is particularly useful in compact switchgear designs where heat management is crucial. Additionally, the material's stability at elevated temperatures ensures that it maintains its insulating and mechanical properties even in high-temperature environments, contributing to the overall reliability of the system.

Environmental Resistance and Durability

Switchgear assemblies are often exposed to harsh environmental conditions, including humidity, dust, and chemical contaminants. FR4 epoxy board demonstrates excellent resistance to these environmental factors, maintaining its electrical and mechanical properties over time. Its low moisture absorption rate prevents degradation of insulation properties in humid conditions, while its chemical resistance protects against corrosion and deterioration. These attributes ensure the longevity and reliability of switchgear assemblies in various installation environments, from indoor substations to outdoor enclosures.

Conclusion

FR4 epoxy board has proven to be an indispensable material in the realm of switchgear and power distribution. Its unique combination of electrical insulation, mechanical strength, and flame-retardant properties makes it ideal for ensuring the safety, reliability, and efficiency of electrical systems. As power distribution networks continue to evolve and face new challenges, the versatility and performance of FR4 epoxy board position it as a crucial component in the design and construction of modern electrical infrastructure. Its ongoing use and development will undoubtedly contribute to the advancement of safer, more reliable power distribution systems in the future.

FAQs

What makes FR4 epoxy board suitable for switchgear applications?

FR4 epoxy board is ideal for switchgear due to its high dielectric strength, excellent mechanical properties, and flame-retardant characteristics. These qualities ensure electrical insulation, structural integrity, and safety in high-voltage environments.

How does FR4 epoxy board contribute to the safety of power distribution systems?

FR4 epoxy board enhances safety through its arc resistance, flame-retardant properties, and ability to maintain stable insulation under various environmental conditions, reducing the risk of electrical faults and fires.

Can FR4 epoxy board withstand high temperatures in switchgear assemblies?

Yes, FR4 epoxy board has excellent thermal stability and can maintain its properties at elevated temperatures, making it suitable for use in switchgear assemblies where heat management is crucial.

Choose J&Q for Your FR4 Epoxy Board Needs in Switchgear and Power Distribution

J&Q, a leading FR4 epoxy board manufacturer, offers high-quality insulating sheets tailored for switchgear and power distribution applications. With over 20 years of production experience and 10 years in foreign trade, our expertise ensures superior products and services. Our in-house logistics company provides seamless one-stop solutions. For more information on our FR4 epoxy board products, contact us at info@jhd-material.com.

References

Johnson, R. T., & Smith, A. B. (2021). Advanced Materials in Electrical Power Systems: A Comprehensive Review.

Zhang, L., et al. (2020). Dielectric Properties and Applications of FR4 Epoxy Board in High Voltage Equipment.

Brown, C. D. (2019). Switchgear Design: Principles and Innovations in Insulation Technology.

Patel, N. K., & Rodriguez, M. (2022). Safety Advancements in Power Distribution: The Role of FR4 Epoxy Materials.

Williams, E. F., & Thompson, G. H. (2018). Thermal Management Strategies in Modern Switchgear Assemblies.

Lee, S. Y., et al. (2023). Environmental Resilience of Insulating Materials in Electrical Infrastructure.