FR4 Epoxy Sheet: A Game-Changer in New Energy Vehicle Manufacturing

Understanding FR4 Epoxy Sheet Composition

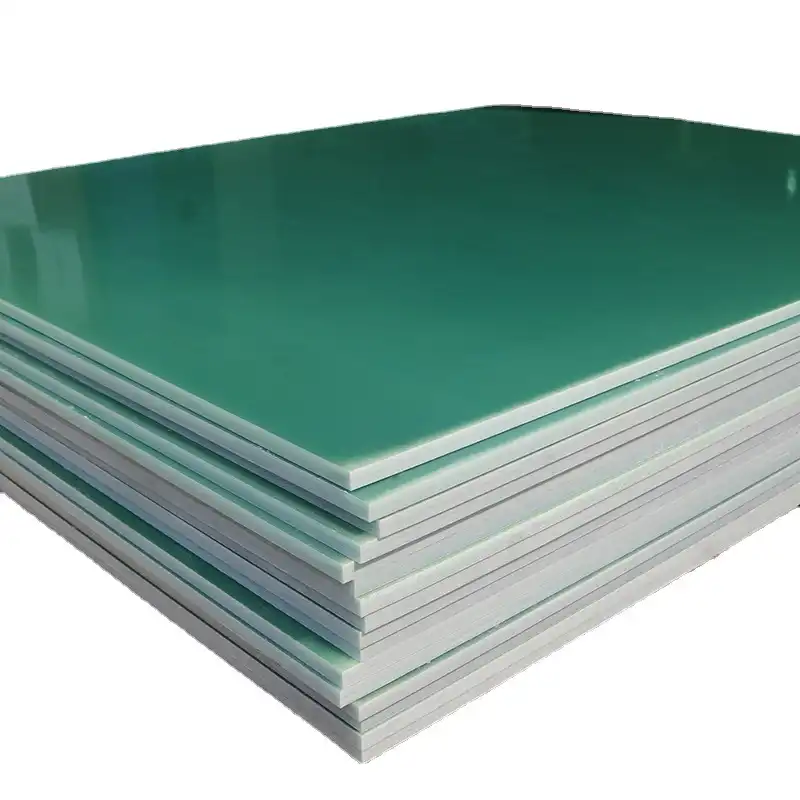

FR4 epoxy sheet, a versatile and robust material, is composed of a woven fiberglass cloth impregnated with an epoxy resin system. This unique combination results in a laminate with exceptional electrical and mechanical properties. The fiberglass provides strength and dimensional stability, while the epoxy resin offers excellent electrical insulation and resistance to moisture absorption. The "FR" in FR4 stands for "flame retardant," indicating its ability to self-extinguish when exposed to fire, a crucial safety feature in automotive applications.

Key Properties Driving FR4 Adoption in New Energy Vehicles

The adoption of FR4 epoxy board in new energy vehicles is primarily driven by its outstanding properties. These include high dielectric strength, low moisture absorption, excellent dimensional stability, and impressive mechanical strength. The material's ability to maintain its properties across a wide temperature range makes it particularly suitable for the demanding environment of electric vehicles. Moreover, FR4's low coefficient of thermal expansion ensures that components remain stable and functional even under fluctuating temperature conditions, which is essential for the reliability of vehicle electronics.

Environmental Benefits of FR4 in Sustainable Vehicle Design

As the automotive industry strives for sustainability, FR4 epoxy sheet aligns well with eco-friendly design principles. The material's durability and resistance to degradation contribute to the longevity of vehicle components, reducing the need for frequent replacements. Additionally, FR4 can be recycled at the end of its life cycle, supporting circular economy initiatives in the automotive sector. The use of FR4 in lightweight designs also indirectly contributes to improved energy efficiency in electric vehicles, further enhancing their environmental credentials.

Critical Applications of FR4 Epoxy Sheet in Electric Vehicle Systems

Battery Management Systems: The Heart of Electric Vehicles

In the realm of electric vehicles, battery management systems (BMS) are paramount, and FR4 epoxy sheet plays a crucial role in their construction. The BMS monitors and controls the battery pack, ensuring optimal performance and safety. FR4 epoxy board serves as the substrate for the printed circuit boards (PCBs) within the BMS, providing a stable and insulating foundation for the complex electronic components. Its high dielectric strength prevents short circuits, while its thermal stability ensures reliable operation even when the battery generates significant heat during charging and discharging cycles.

Power Distribution Units: Efficient Energy Management

Power distribution units (PDUs) in electric vehicles are responsible for efficiently routing electrical power from the battery to various vehicle systems. FR4 epoxy sheet is extensively used in PDU construction due to its excellent electrical insulation properties and ability to withstand high voltages. The material's dimensional stability ensures that the intricate circuit patterns remain precise, even under the vibrations and temperature fluctuations typical in automotive environments. This reliability is crucial for maintaining the vehicle's overall performance and safety.

Electromagnetic Shielding: Protecting Sensitive Electronics

As electric vehicles incorporate more advanced electronic systems, electromagnetic interference (EMI) becomes a significant concern. FR4 epoxy sheet, when combined with appropriate conductive coatings or layers, can serve as an effective electromagnetic shield. This application is particularly important in protecting sensitive electronic components from both internal and external electromagnetic radiation. The use of FR4 in EMI shielding contributes to the overall reliability and performance of the vehicle's electronic systems, ensuring smooth operation of everything from infotainment systems to critical safety features.

Future Trends and Innovations in FR4 Epoxy Sheet for New Energy Vehicles

Advanced Manufacturing Techniques for Enhanced Performance

The future of FR4 epoxy sheet in new energy vehicles is closely tied to advancements in manufacturing techniques. Innovations in precision layering and lamination processes are enabling the production of thinner, lighter FR4 boards without compromising on strength or electrical properties. These advancements are particularly valuable in the automotive sector, where weight reduction is a constant goal. Additionally, new methods of integrating FR4 with other materials, such as embedded cooling systems or conductive layers, are being developed to enhance the multifunctionality of components in electric vehicles.

Smart FR4 Materials for Next-Generation Vehicles

The concept of "smart" materials is gaining traction in the automotive industry, and FR4 epoxy sheet is no exception. Research is underway to develop FR4-based materials with integrated sensing capabilities. These advanced materials could potentially monitor their own condition, detect potential failures before they occur, and even self-heal minor damage. In the context of new energy vehicles, such smart FR4 materials could revolutionize predictive maintenance, enhancing safety and reducing downtime. The integration of nanotechnology in FR4 production is also being explored to further improve its electrical and thermal properties.

Sustainability and Recycling Innovations

As environmental concerns continue to shape the automotive industry, there is a growing focus on improving the sustainability of FR4 epoxy sheet. Researchers are exploring bio-based epoxy resins and more environmentally friendly flame retardants to reduce the ecological footprint of FR4 production. Simultaneously, advancements in recycling technologies are making it easier to recover and reuse the valuable components of FR4 boards at the end of their life cycle. These developments are crucial for aligning FR4 use with the broader sustainability goals of the new energy vehicle sector, ensuring that the material remains a viable and responsible choice for future automotive applications.

Conclusion

The application prospects of FR4 epoxy sheet in new energy vehicles are undeniably bright and expansive. As the automotive industry continues its rapid transition towards electrification, the demand for high-performance, reliable materials like FR4 epoxy board is set to soar. From its critical role in battery management systems and power distribution units to its potential in advanced electromagnetic shielding, FR4 is proving to be an indispensable component in the evolution of electric and hybrid vehicles. The ongoing innovations in FR4 manufacturing, coupled with the development of smart and sustainable variants, ensure that this versatile material will remain at the forefront of new energy vehicle technology for years to come.

Contact Us

Are you interested in learning more about how FR4 epoxy sheet can benefit your new energy vehicle projects? Our team of experts is ready to provide you with detailed information and customized solutions. Contact us today at info@jhd-material.com to discover how our high-quality FR4 epoxy boards can elevate your automotive designs to the next level.