G10 Materials: Properties and Advantages for NEV Applications

Composition and Manufacturing of G10 Sheet

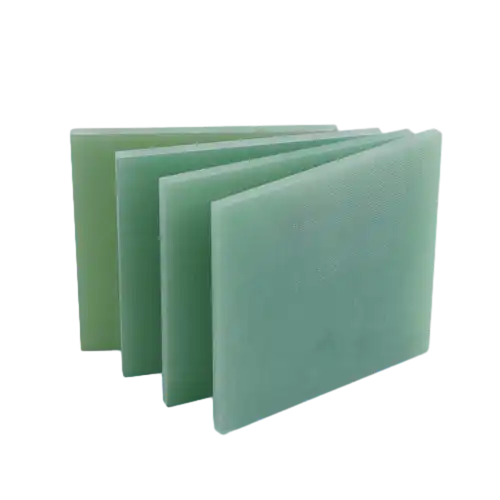

G10 sheet is a high-pressure laminate composed of continuous filament glass fabric impregnated with epoxy resin. The manufacturing process involves layering multiple sheets of glass fabric and impregnating them with epoxy resin under high pressure and temperature. This results in a dense, uniform material with excellent mechanical and electrical properties.

Key Properties of G10 Epoxy Sheet

G10 epoxy sheet boasts an impressive array of properties that make it suitable for NEV applications. These include high dielectric strength, low moisture absorption, excellent dimensional stability, and good machinability. The material also exhibits remarkable mechanical strength, with a high flexural modulus and compressive strength, allowing it to withstand the rigors of automotive use.

Advantages of G10 Materials in NEV Design

The unique combination of properties offered by G10 materials provides several advantages in NEV design. Their excellent electrical insulation properties help protect sensitive electronic components from electromagnetic interference. The high strength-to-weight ratio of G10 sheets contributes to vehicle lightweighting efforts, crucial for improving energy efficiency. Additionally, the thermal stability of G10 materials ensures consistent performance across a wide range of operating temperatures encountered in automotive applications.

Specific Applications of G10 Materials in New Energy Vehicles

Battery Insulation and Management Systems

One of the most critical applications of G10 materials in NEVs is in battery insulation and management systems. G10 sheets are used to create insulating barriers between battery cells, preventing short circuits and thermal runaway. The material's low thermal conductivity also helps in maintaining optimal battery temperature, crucial for maximizing performance and longevity. G10 epoxy sheets are often employed in the construction of battery management system (BMS) housings, providing a stable and insulating platform for sensitive electronic components.

Electric Motor Components

G10 materials find extensive use in electric motor components, particularly in the construction of slot liners and phase separators. The high dielectric strength of G10 sheets ensures effective insulation between motor windings, while their mechanical strength allows them to withstand the high rotational forces present in electric motors. The material's resistance to heat and chemicals also contributes to the longevity of motor components, reducing maintenance requirements and improving overall reliability.

Structural and Non-Structural Components

Beyond electrical applications, G10 materials are increasingly being utilized in both structural and non-structural components of NEVs. Their high strength-to-weight ratio makes them suitable for reinforcing body panels and chassis components, contributing to improved vehicle dynamics and crash safety. G10 sheets are also used in the fabrication of interior components such as instrument panel supports and seat structures, where their dimensional stability and flame-retardant properties are particularly valuable.

Future Trends and Innovations in G10 Material Applications for NEVs

Advanced Manufacturing Techniques

The future of G10 material applications in NEVs is closely tied to advancements in manufacturing techniques. Researchers are exploring novel methods to enhance the properties of G10 sheets, such as nanoparticle reinforcement and 3D printing of composite structures. These innovations aim to further improve the strength, thermal management, and electrical insulation properties of G10 materials, enabling more efficient and compact NEV designs.

Integration with Smart Materials

An exciting area of development is the integration of G10 materials with smart materials and sensors. By incorporating piezoelectric or thermoelectric elements into G10 sheets, manufacturers can create multifunctional components that not only provide structural support and insulation but also generate or harvest energy. This integration has the potential to revolutionize energy management in NEVs, improving overall efficiency and range.

Sustainability and Recyclability

As environmental concerns continue to drive innovation in the automotive industry, there is a growing focus on improving the sustainability and recyclability of G10 materials. Researchers are investigating bio-based epoxy resins and recycled glass fibers as potential alternatives to traditional G10 components. These efforts aim to reduce the environmental impact of NEV production while maintaining the high performance standards required for automotive applications.

Conclusion

The application of G10 materials in new energy vehicles represents a significant advancement in automotive engineering. From crucial roles in battery insulation and electric motor components to innovative structural applications, G10 sheets and G10 epoxy sheets are contributing to the improved performance, safety, and efficiency of NEVs. As the automotive industry continues its transition towards electrification, the demand for high-performance materials like G10 is expected to grow. Future innovations in manufacturing techniques, smart material integration, and sustainability efforts will further enhance the capabilities of G10 materials, solidifying their position as a key enabler in the evolution of new energy vehicles.

Contact Us

To learn more about our G10 materials and how they can benefit your NEV projects, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect G10 solution for your specific application needs.