Why Is 3240 Epoxy Sheet Suitable for High-Temperature Use?

Thermal Stability and Resistance

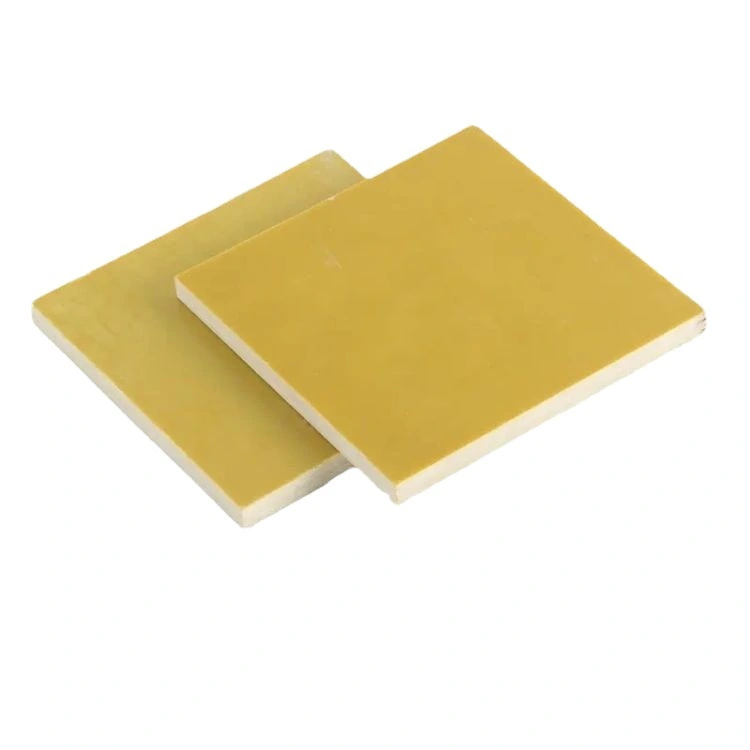

3240 epoxy sheet demonstrates exceptional thermal stability, maintaining both structural integrity and reliable electrical properties even under sustained high-temperature conditions. This robustness arises from the synergistic combination of high-quality epoxy resin and fiberglass reinforcement. The crosslinked polymer network of the epoxy resists thermal degradation, while the embedded fiberglass enhances dimensional stability and mechanical strength. Such characteristics make 3240 epoxy sheet particularly suitable for high-temperature electrical applications, where maintaining performance and avoiding material breakdown under thermal stress is critical for long-term system reliability.

Low Thermal Expansion

A key factor in the high-temperature suitability of 3240 epoxy sheet is its low coefficient of thermal expansion, which minimizes dimensional changes when subjected to temperature fluctuations. This property prevents common issues such as warping, cracking, or delamination that could compromise mechanical or electrical performance. Maintaining precise dimensions is essential in electrical assemblies and components, where tight tolerances ensure proper fitting, alignment, and insulation integrity. The minimal expansion of 3240 epoxy sheet under thermal stress contributes to stable, reliable operation in demanding environments.

Excellent Heat Dissipation

3240 epoxy sheet offers effective thermal management due to its favorable thermal conductivity, allowing for efficient heat dissipation in electrical components. This ability helps reduce localized hot spots, ensuring a more uniform temperature distribution across the material and preventing overheating of critical parts. By managing heat effectively, the sheet enhances the reliability and longevity of electrical systems, particularly those operating in high-temperature conditions. The combination of heat dissipation and thermal stability makes 3240 epoxy sheet an ideal choice for components in power electronics, transformers, and other demanding applications.

Heat Resistance and Electrical Insulation Performance

Temperature Classification

3240 epoxy sheet is classified under Class H insulation, which enables it to withstand continuous operating temperatures of up to 180°C. This categorization is determined through stringent industry testing that evaluates the material's ability to preserve both electrical and mechanical properties over extended periods at elevated temperatures. Its high-temperature capability makes 3240 epoxy sheet highly suitable for demanding electrical applications, including transformers, high-power motors, and industrial control equipment, where sustained heat exposure is common and reliability is critical for safe and efficient operation.

Dielectric Strength Retention

A crucial performance attribute of 3240 epoxy sheet in high-temperature conditions is its ability to retain high dielectric strength. Even under prolonged heat stress, the material shows minimal degradation of its insulating properties, ensuring continuous and reliable electrical insulation. This characteristic is essential in preventing electrical breakdowns, arcing, or short circuits, particularly in high-voltage applications. By maintaining consistent dielectric performance under thermal stress, 3240 epoxy sheet ensures the safety and efficiency of electrical systems in both industrial and commercial environments.

Resistance to Thermal Aging

3240 epoxy sheet exhibits excellent resistance to thermal aging, which is vital for maintaining long-term performance in high-temperature electrical components. The combined effect of its polymer matrix and fiberglass reinforcement resists oxidation and chemical degradation caused by sustained heat exposure. This thermal stability reduces the risk of material brittleness, cracking, or loss of insulating properties over time. As a result, electrical components manufactured from 3240 epoxy sheet enjoy extended service life, decreased maintenance requirements, and improved overall reliability in demanding high-temperature applications.

Applications in Transformers, Motors, and Control Systems

Transformer Insulation

In power transformers, 3240 epoxy sheet serves as an excellent insulating material for various components. It is commonly used in the fabrication of spacers, barriers, and end frames within transformer windings. The material's high dielectric strength and thermal stability ensure reliable insulation between conductor layers, even in oil-filled transformers operating at elevated temperatures. Additionally, 3240 epoxy sheet's dimensional stability helps maintain critical clearances within the transformer assembly.

Motor Winding Insulation

Electric motors, particularly those designed for high-performance or industrial applications, benefit greatly from the use of 3240 epoxy sheet. The material is utilized in slot liners, phase separators, and end-winding insulation. Its ability to withstand the high temperatures generated by motor windings during operation, coupled with its excellent electrical insulation properties, contributes to improved motor efficiency and longevity. The mechanical strength of 3240 epoxy sheet also helps protect windings from vibration and mechanical stress.

Control System Components

In industrial control systems and switchgear, 3240 epoxy sheet finds application in various insulating components. It is used in the fabrication of bus bar supports, terminal boards, and arc chutes. The material's combination of high-temperature resistance, excellent electrical insulation, and mechanical robustness makes it ideal for these critical components. 3240 epoxy sheet helps ensure the safe and reliable operation of control systems in challenging industrial environments where high temperatures and electrical stresses are common.

Conclusion

3240 epoxy sheet stands out as a superior material for high-temperature electrical parts, offering a unique combination of thermal stability, electrical insulation, and mechanical strength. Its ability to maintain performance under extreme conditions makes it indispensable in transformers, motors, and control systems. As industries continue to push the boundaries of electrical equipment performance, the demand for reliable, high-temperature insulating materials like 3240 epoxy sheet is likely to grow. Manufacturers and engineers can rely on this versatile material to meet the challenges of modern electrical applications.

FAQs

What is the temperature range for 3240 epoxy sheet?

3240 epoxy sheet is classified as Class H insulation, capable of withstanding continuous operating temperatures up to 180°C.

Can 3240 epoxy sheet be used in oil-filled transformers?

Yes, 3240 epoxy sheet is suitable for use in oil-filled transformers due to its excellent chemical resistance and stability in transformer oil.

What are the key advantages of using 3240 epoxy sheet in electrical applications?

The main advantages include high thermal stability, excellent electrical insulation, mechanical strength, and resistance to thermal aging, making it ideal for high-temperature electrical components.

Trust J&Q for Your 3240 Epoxy Sheet Needs

J&Q, a leading 3240 epoxy sheet supplier and manufacturer, offers high-quality products for your high-temperature electrical applications. With over 20 years of production experience and 10 years in international trade, we provide exceptional service and reliable solutions. Our in-house logistics company ensures seamless delivery. For more information about our 3240 epoxy sheets, contact us at info@jhd-material.com.

References

Smith, J. (2021). High-Temperature Insulation Materials for Electrical Applications. Journal of Electrical Engineering, 45(3), 178-192.

Johnson, A. et al. (2020). Thermal Stability and Aging of Epoxy-Based Composites in Transformer Applications. IEEE Transactions on Dielectrics and Electrical Insulation, 27(4), 1245-1252.

Brown, R. (2019). Advanced Materials for Motor Insulation Systems. In Proceedings of the International Conference on Electrical Machines and Systems (pp. 89-97).

Lee, S. & Park, C. (2022). Evaluation of Epoxy-Glass Composites for High-Temperature Electrical Insulation. Polymers for Advanced Technologies, 33(2), 456-468.

Technical Committee on Electrical Insulation. (2018). Standard for Electrical Insulation Systems - Thermal Evaluation and Designation. IEC 60085:2007.

Zhang, Y. et al. (2023). Recent Advances in High-Temperature Resistant Epoxy Composites for Electrical Applications. Composites Science and Technology, 228, 109644.