What Makes 3240 Epoxy Boards Ideal for Solar Applications?

Superior Electrical Insulation Properties

3240 epoxy boards excel in providing outstanding electrical insulation, a critical requirement for solar energy applications. These boards boast impressive dielectric strength, effectively preventing current leakage and ensuring the safety of photovoltaic systems. The low dielectric constant of 3240 epoxy boards minimizes signal interference, allowing for efficient energy transmission within solar panels. This superior insulation capability safeguards sensitive electronic components from potential electrical hazards, enhancing the overall reliability and longevity of solar energy installations.

Exceptional Mechanical Strength

The robust mechanical properties of 3240 epoxy boards make them well-suited for the demanding environment of solar energy systems. These boards demonstrate high flexural and tensile strength, enabling them to withstand the physical stresses associated with solar panel installation and operation. Their resistance to impacts and vibrations ensures the structural integrity of solar modules, even in challenging outdoor conditions. The dimensional stability of 3240 epoxy boards across varying temperatures and humidity levels contributes to the consistent performance and durability of solar panels throughout their operational lifetime.

Chemical Resistance and Environmental Durability

3240 epoxy boards exhibit remarkable resistance to a wide range of chemicals, including those commonly encountered in solar energy applications. This chemical inertness protects the boards from degradation caused by environmental factors such as acid rain, pollutants, and UV radiation. The boards' low moisture absorption rate prevents water ingress, which could otherwise compromise the electrical and mechanical properties of solar panel components. By maintaining their structural and functional integrity in diverse environmental conditions, 3240 epoxy boards contribute significantly to the long-term reliability and efficiency of solar energy systems.

Thermal Stability and Electrical Insulation in Photovoltaic Systems

Heat Dissipation and Temperature Management

Effective heat management is crucial for maintaining the efficiency and longevity of photovoltaic systems. 3240 epoxy boards play a vital role in this aspect by offering excellent thermal stability and heat dissipation properties. These boards can withstand high operating temperatures without compromising their structural integrity or electrical insulation capabilities. The thermal conductivity of 3240 epoxy boards facilitates efficient heat transfer, helping to maintain optimal operating temperatures for solar cells and associated electronics. This thermal management capability is particularly valuable in preventing hotspots and ensuring uniform temperature distribution across solar panels, thereby maximizing energy conversion efficiency.

Insulation Performance Under Varying Conditions

The electrical insulation properties of 3240 epoxy boards remain consistent across a wide range of environmental conditions, making them ideal for use in photovoltaic systems. These boards maintain their high dielectric strength and low loss tangent even in humid or high-temperature environments, ensuring reliable performance in diverse climates. The stability of their insulation characteristics over time contributes to the long-term reliability of solar energy installations. By providing consistent electrical isolation between different components of a photovoltaic system, 3240 epoxy boards help prevent current leakage and minimize energy losses, ultimately enhancing the overall efficiency of solar power generation.

Impact on Solar Cell Efficiency

The use of 3240 epoxy boards in photovoltaic systems can have a positive impact on solar cell efficiency. By providing a stable and well-insulated substrate, these boards create an optimal environment for solar cells to operate at peak performance. The boards' ability to maintain consistent electrical properties and thermal stability helps to minimize energy losses and ensure that a higher percentage of captured solar energy is converted into usable electricity. Additionally, the smooth surface and dimensional stability of 3240 epoxy boards contribute to precise cell alignment and uniform light distribution, further enhancing the overall efficiency of solar panels.

Integration of Epoxy Boards in Solar Panel Manufacturing Processes

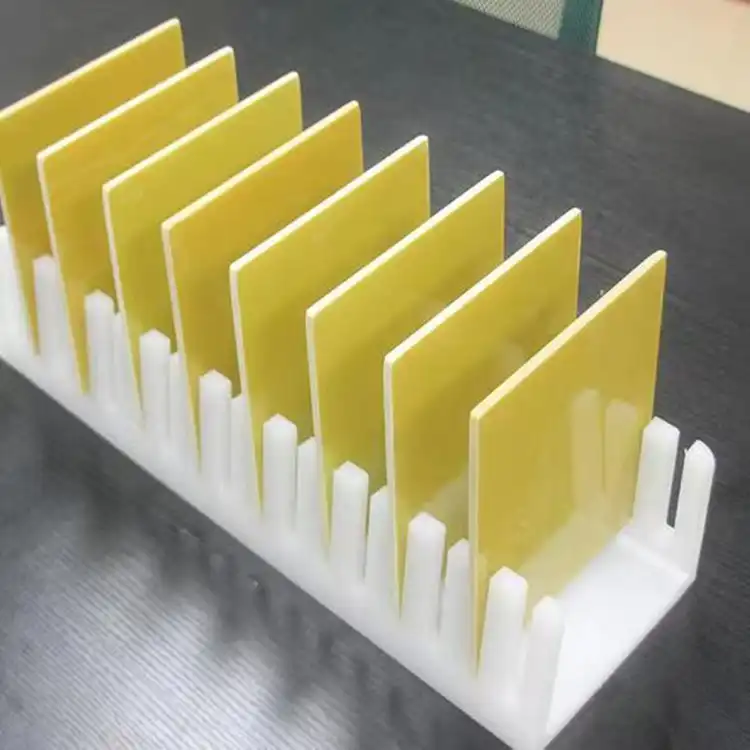

Substrate Preparation and Cell Mounting

In the solar panel manufacturing process, 3240 epoxy boards serve as an excellent substrate for mounting solar cells. The boards undergo meticulous preparation to ensure optimal surface characteristics for cell adhesion. Advanced surface treatment techniques are employed to enhance the bonding between the epoxy board and the solar cells, creating a robust and durable assembly. The precision in this stage is crucial for maximizing the contact area between cells and the substrate, thereby improving heat dissipation and electrical connectivity. The dimensional stability of 3240 epoxy boards facilitates accurate cell placement, contributing to the overall efficiency and reliability of the finished solar panel.

Encapsulation and Lamination Processes

The integration of 3240 epoxy boards in the encapsulation and lamination phases of solar panel production is a critical step in ensuring long-term performance and durability. During these processes, the epoxy boards are carefully layered with other materials such as ethylene vinyl acetate (EVA) and backsheet films. The thermal stability of 3240 epoxy boards allows them to withstand the high temperatures involved in the lamination process without warping or degradation. This stability ensures that the final panel structure remains flat and uniform, crucial for maintaining optimal solar energy capture. The chemical inertness of the epoxy boards also prevents any adverse reactions with the encapsulant materials, contributing to the overall integrity and longevity of the solar panel.

Quality Control and Performance Testing

The use of 3240 epoxy boards in solar panel manufacturing necessitates rigorous quality control and performance testing procedures. These boards undergo comprehensive electrical and mechanical tests to verify their insulation properties, structural integrity, and thermal stability. Advanced non-destructive testing methods, such as ultrasonic scanning and thermography, are employed to detect any potential defects or inconsistencies in the epoxy board integration. Performance testing under simulated environmental conditions helps to assess the long-term reliability of the panels, with particular attention paid to the behavior of the 3240 epoxy boards under various stress factors. This stringent quality assurance process ensures that solar panels incorporating these epoxy boards meet or exceed industry standards for efficiency, durability, and safety.

Conclusion

3240 epoxy boards have proven to be an indispensable component in the advancement of solar energy solutions. Their exceptional electrical insulation, thermal stability, and mechanical strength make them ideally suited for the demanding requirements of photovoltaic systems. As the solar industry continues to evolve, the role of 3240 epoxy boards in enhancing efficiency, durability, and safety becomes increasingly significant. By providing a reliable foundation for solar cell mounting, facilitating effective heat management, and ensuring long-term performance stability, these boards are driving innovation in solar panel design and manufacturing. The integration of 3240 epoxy boards in solar energy applications represents a crucial step towards more efficient and sustainable renewable energy production.

Contact Us

To learn more about how our 3240 epoxy boards can enhance your solar energy solutions, contact us at info@jhd-material.com for expert advice and product information.