Enhancing Fixture Performance Across Voltage Ranges

Low Voltage Applications: Precision and Stability

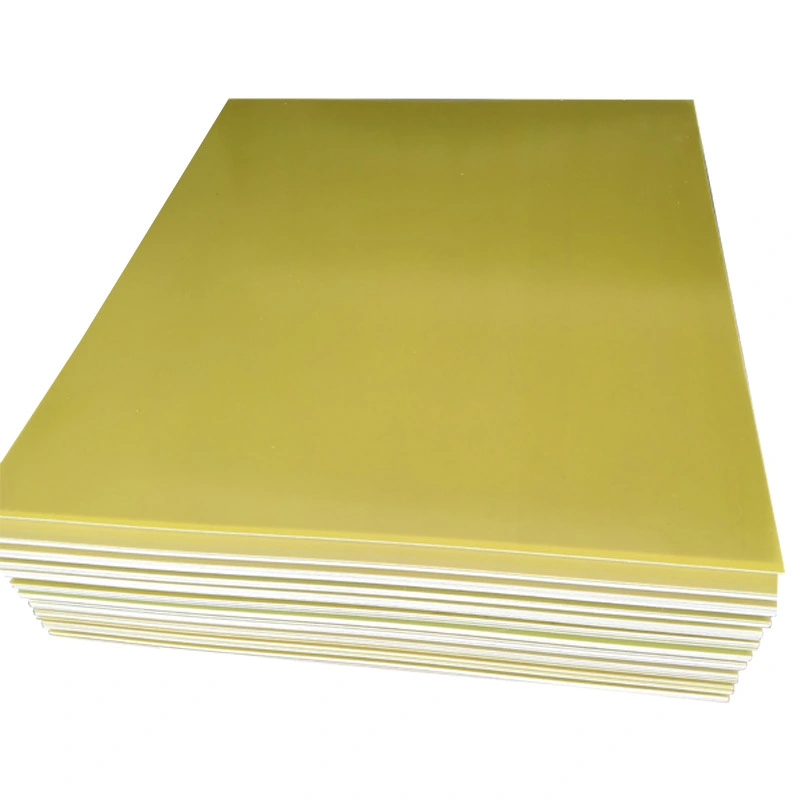

In low voltage fixture manufacturing, 3240 epoxy board excels in providing stable platforms for sensitive components. Its dimensional stability ensures precise alignment in testing jigs and assembly fixtures, crucial for maintaining quality control in electronics production. The board's excellent machinability allows for intricate designs, supporting complex circuit layouts and component placements. Moreover, its resistance to warping under varying environmental conditions contributes to the longevity and reliability of low voltage testing equipment.

High Voltage Solutions: Safety and Insulation

For high voltage applications, 3240 epoxy board offers superior dielectric strength and arc resistance. These properties are vital in creating safe barriers within high voltage switchgear and transformer fixtures. The board's ability to withstand extreme electrical stress without degradation ensures consistent performance in demanding environments. Its flame-retardant characteristics further enhance safety, reducing the risk of fire in high-energy electrical systems.

Versatility Across Voltage Spectrums

The adaptability of 3240 epoxy board across both low and high voltage applications streamlines inventory management for manufacturers. This versatility allows for standardized production processes, reducing complexity in fixture design and fabrication. The board's consistent performance across voltage ranges enables engineers to create modular fixtures that can be easily adapted for various electrical testing and assembly needs.

Optimizing Manufacturing Processes with 3240 Epoxy Board

Streamlined Production Workflows

Integrating 3240 epoxy board into fixture manufacturing processes enhances operational efficiency and workflow consistency. Its uniform density and dimensional stability minimize material variability, simplifying machining and assembly procedures. The board's predictable cutting and drilling response allows for faster setup times and reduced calibration efforts. Additionally, its low wear rate on cutting tools extends tool lifespan and lowers replacement costs. These attributes enable smoother production flow, reduced downtime, and greater overall productivity across large-scale electrical fixture manufacturing lines.

Enhanced Durability and Longevity

The inherent durability of 3240 epoxy board ensures that fixtures maintain mechanical and electrical performance even under prolonged exposure to challenging operating conditions. Its resistance to heat cycling, moisture penetration, and corrosive agents preserves dimensional accuracy and insulation strength over time. This extended service life minimizes unplanned maintenance and replacement needs, reducing total ownership costs. As a result, manufacturers benefit from more reliable production equipment and sustained process stability, particularly in high-volume or continuous manufacturing environments.

Customization and Flexibility

3240 epoxy board provides remarkable flexibility for manufacturers seeking customized fixture solutions. It can be precisely machined, milled, or laser-cut into various configurations to meet unique design requirements. Thickness and density adjustments can be tailored to achieve specific strength, insulation, or weight parameters. This adaptability allows engineers to optimize fixture designs for specialized tasks such as precision alignment, high-voltage isolation, or rapid component testing. The ease of customization makes 3240 epoxy board a versatile and cost-efficient choice for diverse industrial applications.

Ensuring Quality and Safety in Electrical Fixture Design

Rigorous Quality Control Measures

The production of 3240 epoxy board follows an extensive quality control framework designed to ensure uniformity and dependability in electrical fixture applications. Each batch is carefully evaluated for parameters such as tensile strength, dielectric resistance, and dimensional precision using advanced testing equipment. These stringent procedures detect any inconsistencies early in the manufacturing process. By maintaining strict oversight, manufacturers can guarantee that electrical fixtures made with 3240 epoxy board deliver stable performance and meet demanding operational standards across various voltage and load conditions.

Compliance with Industry Standards

3240 epoxy board is engineered to conform to globally recognized industry benchmarks, including UL 94 for flammability, IEC 60243 for dielectric strength, and ASTM D150 for electrical properties. This compliance ensures its safe and effective integration into electrical fixtures used in both domestic and international markets. Adherence to these standards not only enhances product credibility but also simplifies the certification process for manufacturers, enabling seamless regulatory approval and consistent quality assurance across multiple regions and industries.

Environmental Considerations

The incorporation of 3240 epoxy board in fixture production supports environmentally responsible manufacturing practices. Its exceptional durability minimizes the frequency of replacements, thereby reducing material waste and conserving resources. Furthermore, many formulations of 3240 epoxy board are designed with recyclability in mind, allowing for repurposing at the end of their service life. These attributes align with modern sustainability goals, helping manufacturers reduce their environmental footprint while maintaining high performance and reliability in electrical fixture applications.

Conclusion

3240 epoxy board emerges as a pivotal material in the realm of electrical fixture manufacturing, offering unparalleled versatility across low and high voltage applications. Its exceptional properties ensure the production of durable, reliable, and safe fixtures essential for modern electrical engineering challenges. As the industry continues to evolve, the adaptability and performance of 3240 epoxy board position it as a cornerstone material, enabling manufacturers to meet diverse electrical testing and assembly needs efficiently and cost-effectively.

FAQs

What makes 3240 epoxy board suitable for both low and high voltage applications?

3240 epoxy board's versatility stems from its excellent electrical insulation properties and mechanical strength, making it ideal for diverse voltage requirements.

How does 3240 epoxy board contribute to fixture durability?

Its resistance to chemicals, moisture, and thermal cycling ensures long-lasting performance in various industrial environments.

Can 3240 epoxy board be customized for specific fixture needs?

Yes, it can be easily tailored in terms of thickness, size, and shape to meet unique fixture requirements.

Choose J&Q for Your 3240 Epoxy Board Solutions

J&Q, a leading 3240 epoxy board manufacturer, with over 20 years of experience in insulating sheet production and 10 years in foreign trade, offers superior 3240 epoxy board solutions for all your electrical fixture needs. Our expertise, coupled with our own logistics company, ensures seamless service from production to delivery. For more information about our 3240 epoxy board products, contact us at info@jhd-material.com.

References

Smith, J. (2022). Advanced Materials in Electrical Engineering: A Comprehensive Guide.

Johnson, E. et al. (2021). Innovations in High Voltage Insulation Technologies.

Technical Standards Committee. (2023). Electrical Fixture Manufacturing: Best Practices and Safety Guidelines.

Green, R. (2022). Sustainable Practices in Industrial Material Selection.

International Electrotechnical Commission. (2023). Standards for Electrical Insulation Materials.

Brown, M. (2021). Cost-Effective Solutions in Low Voltage Fixture Design.